Products

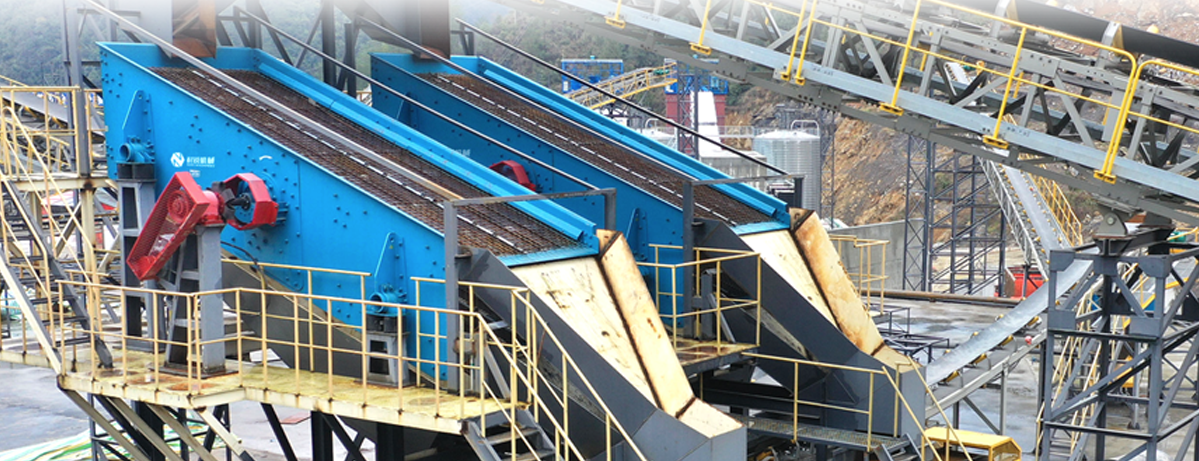

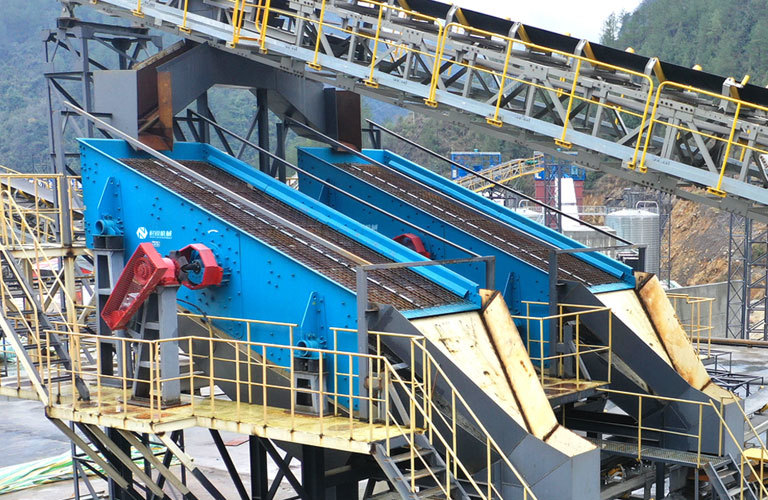

Round vibrating screen

Category:

Product Description

YKR series round vibrating screen is suitable for various screening operations such as heavy-duty, medium and fine screening, and is an ideal equipment for processing primary crushing and secondary crushed materials, and can also be used to screen finished materials. The vibration amplitude can be adjusted, with long material screening line, multi-layer screening, clear screening of different sizes , screening efficiency is high. Suitable for screening sand and gravel in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

01.High screening efficiency

equipped with modular exciter, vibration intensity up to 4.2G, strong processing capacity, high screening efficiency.

02.Strong bearing capacity

built with integral frame structure, compared with the traditional single beam design, the bearing capacity is stronger.

03. Strong excitation force

block eccentricity is used as excitation force, strong excitation force.

04. High self-strength

using the whole plate laser cutting technology, the cutting position is neat, no flying spurs, to ensure the strength of the material itself.

05. Convenient and fast maintenance

simple structure of screening machine, convenient and fast maintenance.

06. Stable operation and long service life

using tire coupling, flexible connection, stable operation. high screening efficiency, large processing capacity and long life.

|

Model |

Number of layers |

Screen hole size (mm) |

Dual amplitude (mm) |

Vibration times (r/min) |

Maximum feed particle size (mm) |

Production capacity (t/h) |

Power (kw) |

|

YKR1645 |

1/2/3 |

3-150 |

7-8 |

970 |

≤150 |

50-350 |

11/15/22 |

|

YKR1845 |

1/2/3 |

3-150 |

7-8 |

970 |

≤200 |

55-450 |

22/30/30 |

|

YKR1854 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

60-480 |

22/30/30/45 |

|

YKR1860 |

1/2/3 |

3-150 |

7-8 |

850 |

≤200 |

80-500 |

22/30/37 |

|

YKR2052 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

90-650 |

15/22/37145 |

|

YKR2160 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

100-750 |

22/30/37145 |

|

YKR2460 |

1/2/3 |

3-150 |

7-8 |

850 |

≤200 |

120-880 |

30/37145 |

|

YKR2475 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-950 |

37145/55 |

|

YKR2773 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-1000 |

37145/55 |

|

YKR3060 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-900 |

37/45/55 |

|

YKR3073 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-1100 |

45/55/2x30 |

|

YKR3675 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

200-1200 |

2x(22/30/37) |

Remarks: Production capacity listed above is determined for dry granding with 1.6t/m³ looseness density.

YKR series round vibrating screen is suitable for various screening operations such as heavy-duty, medium and fine screening, and is an ideal equipment for processing primary crushing and secondary crushed materials, and can also be used to screen finished materials. The vibration amplitude can be adjusted, with long material screening line, multi-layer screening, clear screening of different sizes , screening efficiency is high. Suitable for screening sand and gravel in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

01.High screening efficiency

equipped with modular exciter, vibration intensity up to 4.2G, strong processing capacity, high screening efficiency.

02.Strong bearing capacity

built with integral frame structure, compared with the traditional single beam design, the bearing capacity is stronger.

03. Strong excitation force

block eccentricity is used as excitation force, strong excitation force.

04. High self-strength

using the whole plate laser cutting technology, the cutting position is neat, no flying spurs, to ensure the strength of the material itself.

05. Convenient and fast maintenance

simple structure of screening machine, convenient and fast maintenance.

06. Stable operation and long service life

using tire coupling, flexible connection, stable operation. high screening efficiency, large processing capacity and long life.

|

Model |

Number of layers |

Screen hole size (mm) |

Dual amplitude (mm) |

Vibration times (r/min) |

Maximum feed particle size (mm) |

Production capacity (t/h) |

Power (kw) |

|

YKR1645 |

1/2/3 |

3-150 |

7-8 |

970 |

≤150 |

50-350 |

11/15/22 |

|

YKR1845 |

1/2/3 |

3-150 |

7-8 |

970 |

≤200 |

55-450 |

22/30/30 |

|

YKR1854 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

60-480 |

22/30/30/45 |

|

YKR1860 |

1/2/3 |

3-150 |

7-8 |

850 |

≤200 |

80-500 |

22/30/37 |

|

YKR2052 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

90-650 |

15/22/37145 |

|

YKR2160 |

1/2/3/4 |

3-150 |

7-8 |

850 |

≤200 |

100-750 |

22/30/37145 |

|

YKR2460 |

1/2/3 |

3-150 |

7-8 |

850 |

≤200 |

120-880 |

30/37145 |

|

YKR2475 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-950 |

37145/55 |

|

YKR2773 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-1000 |

37145/55 |

|

YKR3060 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-900 |

37/45/55 |

|

YKR3073 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

150-1100 |

45/55/2x30 |

|

YKR3675 |

1/2/3 |

3-150 |

7-9 |

800 |

≤200 |

200-1200 |

2x(22/30/37) |

Remarks: Production capacity listed above is determined for dry granding with 1.6t/m³ looseness density.

Previous:

Next:

Key words:

Product Brief

Message

Related products