Products

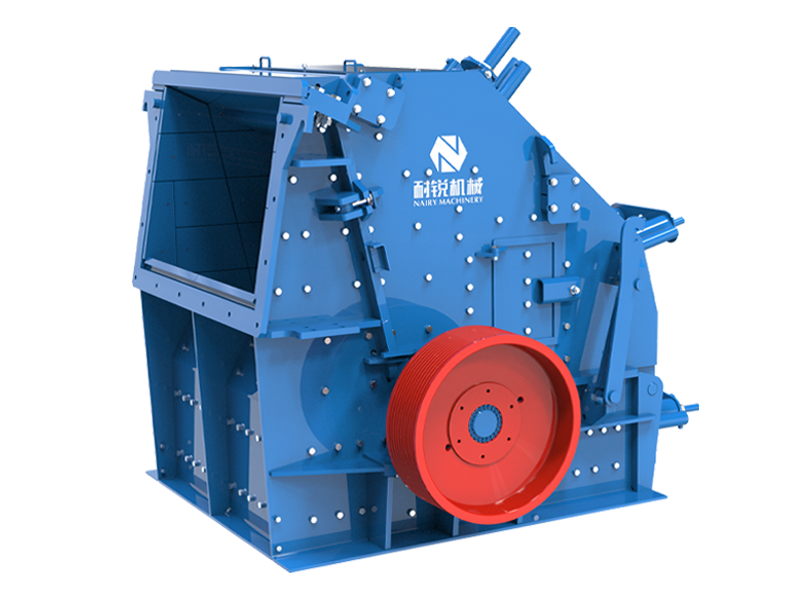

Impact crusher

Category:

Product Description

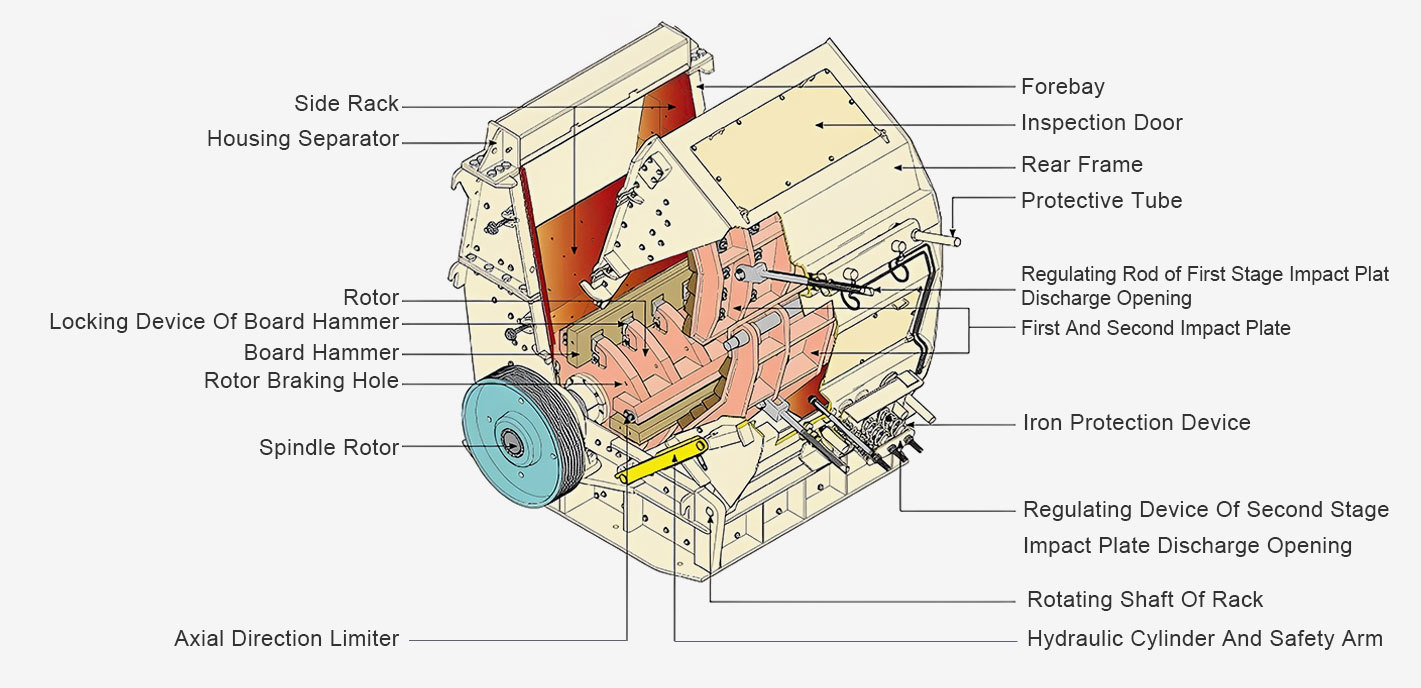

NIC series impact crusher is developed with new design principle and new concept crushing technology, can crush materials of different sizes completely meet the requirements of the new process “more crushing and less grinding”.The application of the principle,“the striking the iron” makes the impact crusher not only larger crushing ratio, but also low power consumption per unit, is a real high efficiency and energy saving crushing equipment.Meanwhile,long-term practice and large projects also proved that impact crusher has a bright application prospect in mineral processing.It has selective crushing effect.The crushed particle size is uniform, mostly of cube stones. Widely used in construction of bridges, highway, port and airport.

NIC series impact crusher is developed with new design principle and new concept crushing technology, can crush materials of different sizes completely meet the requirements of the new process “more crushing and less grinding”.The application of the principle,“the striking the iron” makes the impact crusher not only larger crushing ratio, but also low power consumption per unit, is a real high efficiency and energy saving crushing equipment.Meanwhile,long-term practice and large projects also proved that impact crusher has a bright application prospect in mineral processing.It has selective crushing effect.The crushed particle size is uniform, mostly of cube stones. Widely used in construction of bridges, highway, port and airport.

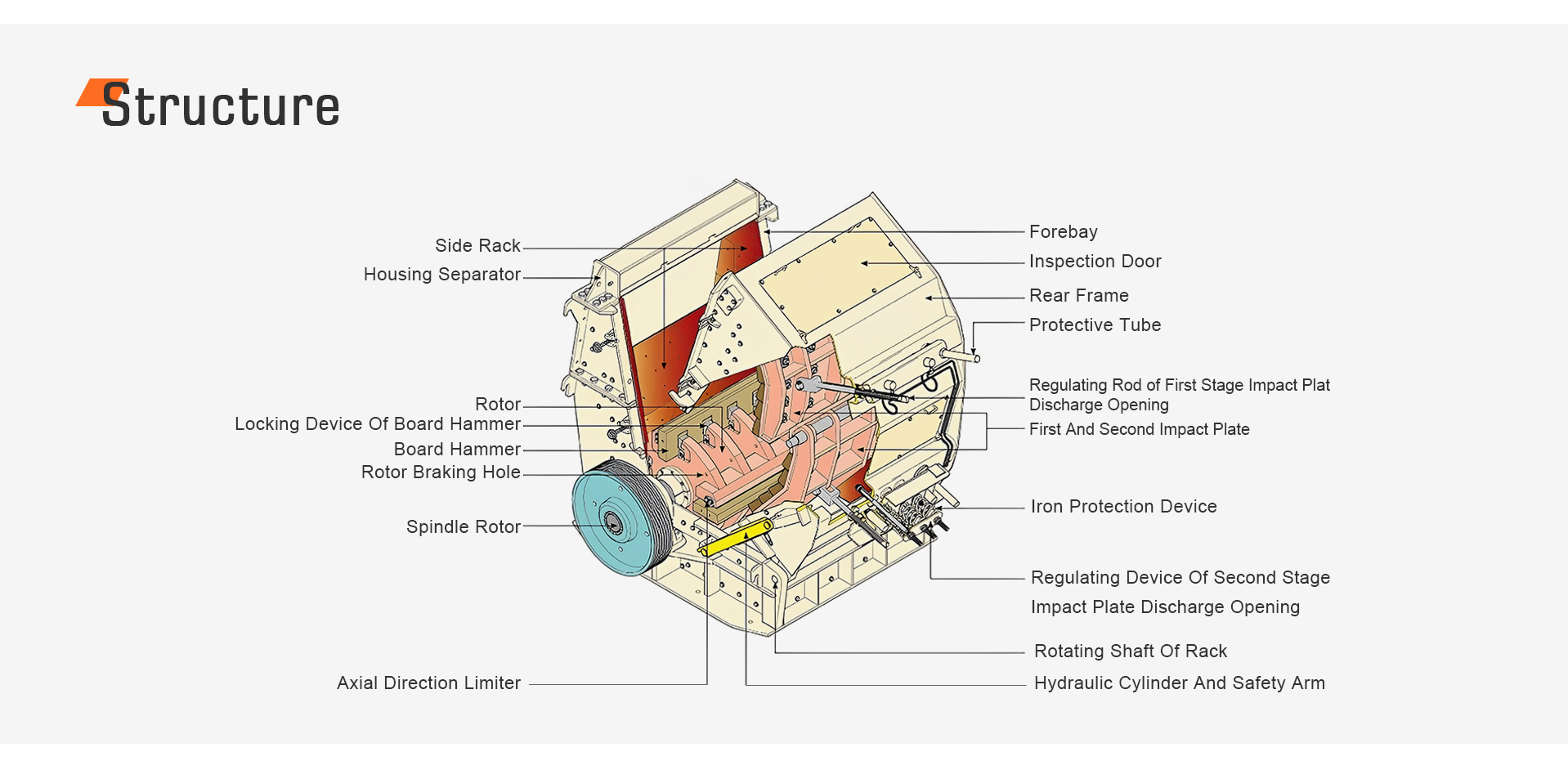

01.High crushing ratio, is simple and reasonable structure. Stable operation , easy maintenance and replacement.High crushing efficiency.Mainly used for crushing medium hard and brittle materials.

01.High crushing ratio, is simple and reasonable structure. Stable operation , easy maintenance and replacement.High crushing efficiency.Mainly used for crushing medium hard and brittle materials.

02.With optimized design,crushing chamber and the feeding particle size is larger. Moreover, with optimized lining plate and specific rotor, the production efficiency under various application conditions is improved.

03.The hammer of the rotor, impact liner plate and other wearing parts of chamber are made of the high chromium and high manganese materials which improves the durability of wearing parts and the reliability of crusher mechanical parts(main shaft and bearing) .

04.Easy maintenance, could be equipped with hydraulic cover, to facilitate changing and replacing of wearing parts.

05.The equipment can adjust space between the impact plate and the board hammer effectively control the discharge particle size.Shape is good.

| Model | Power | Feeding port size(mm) | Maximum feed particle size (mm) | Capacity(t/h) | Rotor diameter (mm) | Rotor width (mm) | Dimension(mm) | Weight(kg) | |

| Coarse crushing series | NIC1313 | 200 | 1320*1225 | 700 | 200-250 | 1300 | 1300 | 3396*2560*3765 | 17800 |

| NIC1415 | 250 | 1540*1320 | 800 | 250-400 | 1400 | 1500 | 3395*3790*4000 | 21815 | |

| NIC1620 | 400(2*200) | 2040*1634 | 1000 | 600-800 | 1600 | 2000 | 3935*3600*4950 | 40500 | |

| NIC2023 | 1000(2*500) | 2310*1986 | 1200 | 800-1200 | 2000 | 2300 | 5731*4424*6000 | 74230 | |

| Medium crushing series | NIC1110 | 160 | 1020*820 | 300 | 80-150 | 1100 | 1000 | 2826*2106*3055 | 9250 |

| NIC1213 | 200 | 1320*879 | 300 | 180-280 | 1200 | 1300 | 3170*2529*3145 | 12780 | |

| NIC1315 | 250 | 1540*930 | 400 | 200-320 | 1300 | 1500 | 3265*2750*3395 | 16130 | |

| NIC1520 | 400(2*200) | 2040*995 | 400 | 350-600 | 1500 | 2000 | 3818*3400*3950 | 27100 | |

NIC series impact crusher is developed with new design principle and new concept crushing technology, can crush materials of different sizes completely meet the requirements of the new process “more crushing and less grinding”.The application of the principle,“the striking the iron” makes the impact crusher not only larger crushing ratio, but also low power consumption per unit, is a real high efficiency and energy saving crushing equipment.Meanwhile,long-term practice and large projects also proved that impact crusher has a bright application prospect in mineral processing.It has selective crushing effect.The crushed particle size is uniform, mostly of cube stones. Widely used in construction of bridges, highway, port and airport.

01.High crushing ratio, is simple and reasonable structure. Stable operation , easy maintenance and replacement.High crushing efficiency.Mainly used for crushing medium hard and brittle materials.

02.With optimized design,crushing chamber and the feeding particle size is larger. Moreover, with optimized lining plate and specific rotor, the production efficiency under various application conditions is improved.

03.The hammer of the rotor, impact liner plate and other wearing parts of chamber are made of the high chromium and high manganese materials which improves the durability of wearing parts and the reliability of crusher mechanical parts(main shaft and bearing) .

04.Easy maintenance, could be equipped with hydraulic cover, to facilitate changing and replacing of wearing parts.

05.The equipment can adjust space between the impact plate and the board hammer effectively control the discharge particle size.Shape is good.

| Model | Power | Feeding port size(mm) | Maximum feed particle size (mm) | Capacity(t/h) | Rotor diameter (mm) | Rotor width (mm) | Dimension(mm) | Weight(kg) | |

| Coarse crushing series | NIC1313 | 200 | 1320*1225 | 700 | 200-250 | 1300 | 1300 | 3396*2560*3765 | 17800 |

| NIC1415 | 250 | 1540*1320 | 800 | 250-400 | 1400 | 1500 | 3395*3790*4000 | 21815 | |

| NIC1620 | 400(2*200) | 2040*1634 | 1000 | 600-800 | 1600 | 2000 | 3935*3600*4950 | 40500 | |

| NIC2023 | 1000(2*500) | 2310*1986 | 1200 | 800-1200 | 2000 | 2300 | 5731*4424*6000 | 74230 | |

| Medium crushing series | NIC1110 | 160 | 1020*820 | 300 | 80-150 | 1100 | 1000 | 2826*2106*3055 | 9250 |

| NIC1213 | 200 | 1320*879 | 300 | 180-280 | 1200 | 1300 | 3170*2529*3145 | 12780 | |

| NIC1315 | 250 | 1540*930 | 400 | 200-320 | 1300 | 1500 | 3265*2750*3395 | 16130 | |

| NIC1520 | 400(2*200) | 2040*995 | 400 | 350-600 | 1500 | 2000 | 3818*3400*3950 | 27100 | |

Previous:

Key words:

Product Description

Product feature

Message

Related products