Products

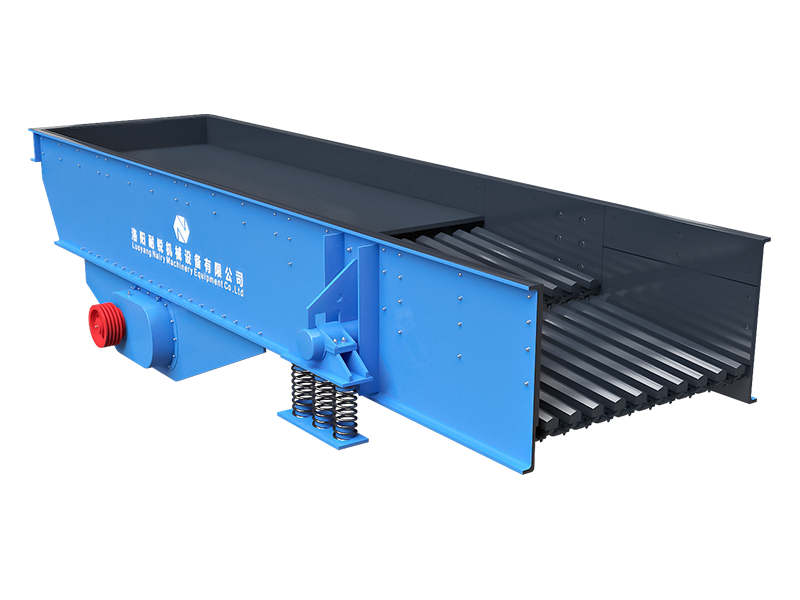

Grizzly feeder

Category:

Product Description

Product Description

ZSW series grizzly feeder is developed by Nairy on the basis of years of experiences in mining designing, production and servicing, combined with existing feeder. It is mainly used for continuous and uniform feeding before coarse crusher. Meanwhile, it can pre-screen fine material to increase the passing amount and improve production efficiency. This machine can be divided into grid plate and grid section.With the development of modern technology, while widely absorbing world advanced technology, Nairy independently developed and designed the new grid plate of the feeder,which is mostly used in conditions of less soil and more bulk materials in raw materials .The feeder with grid section is used for coarse screening of materials with large soil content.

Applicable

Metallurgy, coal mining, mineral processing, building materials, chemical, abrasive and other industries.

Performance

1. Compact structure and easy to adjust and install; It has double eccentric shaft vibrator,so the vibration frequency is high, the vibration force is strong, and the feeding capacity is greatly improved.

2. Use the high grade steel,the steel is resistant to tear and tortuous, with strong bearing capacity. Q345R steel plate is used for side plate and back brace plate, NM wear-resistant steel is used for bottom guard plate and side guard plate, ZGMn13 high manganese steel is used for grid section, which has impact resistance and long service life.

3. Adopt frequency conversion control, feed accurately. Using frequency conversion control, equipment starts and adjusts more smoothly,feed evenly and accurately.

4. process optimization and increase efficiency.Equipped with grid section, the material can be pre-screened,at the same time, according to the process requirements of the production line, to adjust the clearance of the grid section, and thus optimize the process and improve the efficiency.

Technical Parameters

|

Model |

Max.feeding size (mm) |

Rotate Speed (r/min) |

Capacity (t/h) |

Power (kw) |

|

ZSW380×95 |

500 |

500-800 |

-150 |

11 |

|

ZSW420x110 |

580 |

500-800 |

150-280 |

15 |

|

ZSW490x110 |

580 |

500-800 |

150-350 |

18.5 |

|

ZSW600×130 |

750 |

500-800 |

220-580 |

30 |

|

ZSW600x150 |

900 |

500-800 |

260-620 |

37 |

|

ZSW600x180 |

1050 |

600-850 |

400-1000 |

45 |

|

ZSW600x210 |

1200 |

600-850 |

550-1250 |

45 |

Remarks: The above parameters is for reference only. The processing amount involved is subject to the angle of vibration feeder, bar clearance, vibration frequency, material type and the actual site situation.

Product Description

ZSW series grizzly feeder is developed by Nairy on the basis of years of experiences in mining designing, production and servicing, combined with existing feeder. It is mainly used for continuous and uniform feeding before coarse crusher. Meanwhile, it can pre-screen fine material to increase the passing amount and improve production efficiency. This machine can be divided into grid plate and grid section.With the development of modern technology, while widely absorbing world advanced technology, Nairy independently developed and designed the new grid plate of the feeder,which is mostly used in conditions of less soil and more bulk materials in raw materials .The feeder with grid section is used for coarse screening of materials with large soil content.

Applicable

Metallurgy, coal mining, mineral processing, building materials, chemical, abrasive and other industries.

Performance

1. Compact structure and easy to adjust and install; It has double eccentric shaft vibrator,so the vibration frequency is high, the vibration force is strong, and the feeding capacity is greatly improved.

2. Use the high grade steel,the steel is resistant to tear and tortuous, with strong bearing capacity. Q345R steel plate is used for side plate and back brace plate, NM wear-resistant steel is used for bottom guard plate and side guard plate, ZGMn13 high manganese steel is used for grid section, which has impact resistance and long service life.

3. Adopt frequency conversion control, feed accurately. Using frequency conversion control, equipment starts and adjusts more smoothly,feed evenly and accurately.

4. process optimization and increase efficiency.Equipped with grid section, the material can be pre-screened,at the same time, according to the process requirements of the production line, to adjust the clearance of the grid section, and thus optimize the process and improve the efficiency.

Technical Parameters

|

Model |

Max.feeding size (mm) |

Rotate Speed (r/min) |

Capacity (t/h) |

Power (kw) |

|

ZSW380×95 |

500 |

500-800 |

-150 |

11 |

|

ZSW420x110 |

580 |

500-800 |

150-280 |

15 |

|

ZSW490x110 |

580 |

500-800 |

150-350 |

18.5 |

|

ZSW600×130 |

750 |

500-800 |

220-580 |

30 |

|

ZSW600x150 |

900 |

500-800 |

260-620 |

37 |

|

ZSW600x180 |

1050 |

600-850 |

400-1000 |

45 |

|

ZSW600x210 |

1200 |

600-850 |

550-1250 |

45 |

Remarks: The above parameters is for reference only. The processing amount involved is subject to the angle of vibration feeder, bar clearance, vibration frequency, material type and the actual site situation.

Next:

Key words:

Applicable

Product Description

Message

Related products