Products

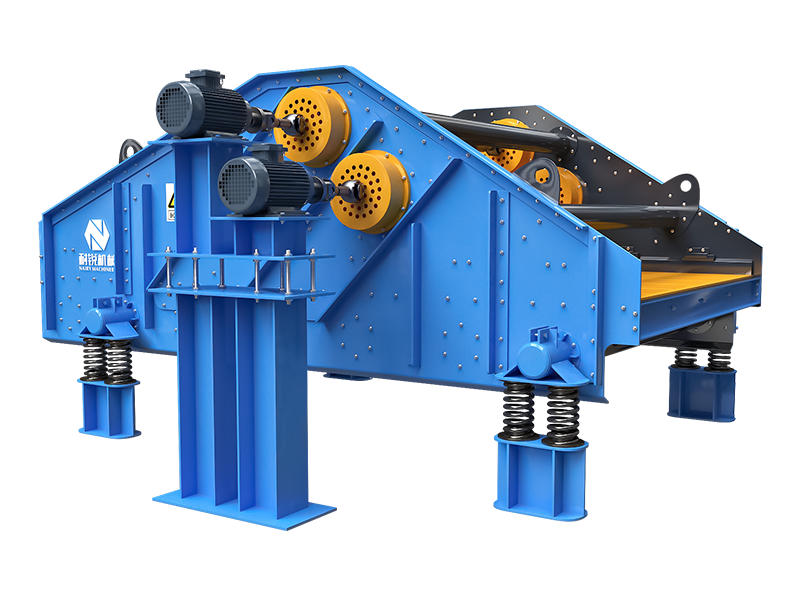

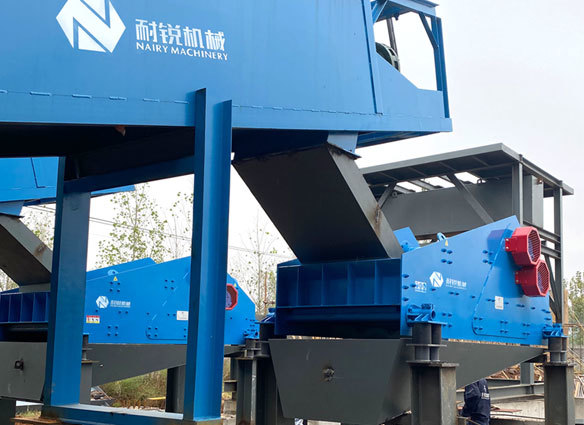

Linear vibrating screen

Category:

Product Description

ZKR series liner vibrating screen is widely used in artificial sand making production line, aggregate processing system in hydropower stations, and dewatering and recycle of coarse slime in coal preparation plant, can effectively solve the problem of water content.

01.With high frequency and large output,can effectively reduce water content in fine sand.

02.Use high-quality manganese steel, integral grider profil design and completely destressed.

03.CNC machining of side plate and protective plate, high-strength Huck bolt link, no soldering seam.

04.Can design corresponding solutions according to different requirements of users.

05.The sieve plate adopts polyurethane or stainless steel strip seam sieve plate, modular installation, local replacement local wearing for low cost of spare parts, longer service life than conventional screen, and not easy to block holes.

|

Model |

Screen size (mm) |

Inclination (°) |

Dual amplitude (mm) |

Maximum feed particle size (mm) |

Production capacity (t/h) |

Power (kw) |

|

ZKR1230 |

0.25-50 |

-5~5 |

6-9 |

150 |

20-100 |

2×4 |

|

ZKR1437 |

0.25-50 |

-5~5 |

6-9 |

150 |

20-120 |

2×5.5 |

|

ZKR1845 |

0.25-50 |

-5~5 |

6-9 |

150 |

50-180 |

2×11 |

|

ZKR1860 |

0.25-50 |

-5~5 |

6-9 |

150 |

50-180 |

2×11 |

|

ZKR2160 |

0.25-50 |

-5~5 |

6-9 |

150 |

70-260 |

2×15 |

|

ZKR2445 |

0.25-50 |

-5~5 |

6-9 |

150 |

100-320 |

2×15 |

|

ZKR2460 |

0.25-50 |

-5~5 |

6-9 |

150 |

100-320 |

2×15 |

|

ZKR3060 |

0.25-50 |

-5~5 |

6-9 |

150 |

150-500 |

2×22 |

Note: The above data is for reference only, please consult with our engineers for specific applications.

ZKR series liner vibrating screen is widely used in artificial sand making production line, aggregate processing system in hydropower stations, and dewatering and recycle of coarse slime in coal preparation plant, can effectively solve the problem of water content.

01.With high frequency and large output,can effectively reduce water content in fine sand.

02.Use high-quality manganese steel, integral grider profil design and completely destressed.

03.CNC machining of side plate and protective plate, high-strength Huck bolt link, no soldering seam.

04.Can design corresponding solutions according to different requirements of users.

05.The sieve plate adopts polyurethane or stainless steel strip seam sieve plate, modular installation, local replacement local wearing for low cost of spare parts, longer service life than conventional screen, and not easy to block holes.

|

Model |

Screen size (mm) |

Inclination (°) |

Dual amplitude (mm) |

Maximum feed particle size (mm) |

Production capacity (t/h) |

Power (kw) |

|

ZKR1230 |

0.25-50 |

-5~5 |

6-9 |

150 |

20-100 |

2×4 |

|

ZKR1437 |

0.25-50 |

-5~5 |

6-9 |

150 |

20-120 |

2×5.5 |

|

ZKR1845 |

0.25-50 |

-5~5 |

6-9 |

150 |

50-180 |

2×11 |

|

ZKR1860 |

0.25-50 |

-5~5 |

6-9 |

150 |

50-180 |

2×11 |

|

ZKR2160 |

0.25-50 |

-5~5 |

6-9 |

150 |

70-260 |

2×15 |

|

ZKR2445 |

0.25-50 |

-5~5 |

6-9 |

150 |

100-320 |

2×15 |

|

ZKR2460 |

0.25-50 |

-5~5 |

6-9 |

150 |

100-320 |

2×15 |

|

ZKR3060 |

0.25-50 |

-5~5 |

6-9 |

150 |

150-500 |

2×22 |

Note: The above data is for reference only, please consult with our engineers for specific applications.

Previous:

Next:

Key words:

Product Overview

Product Features

Message

Related products