Products

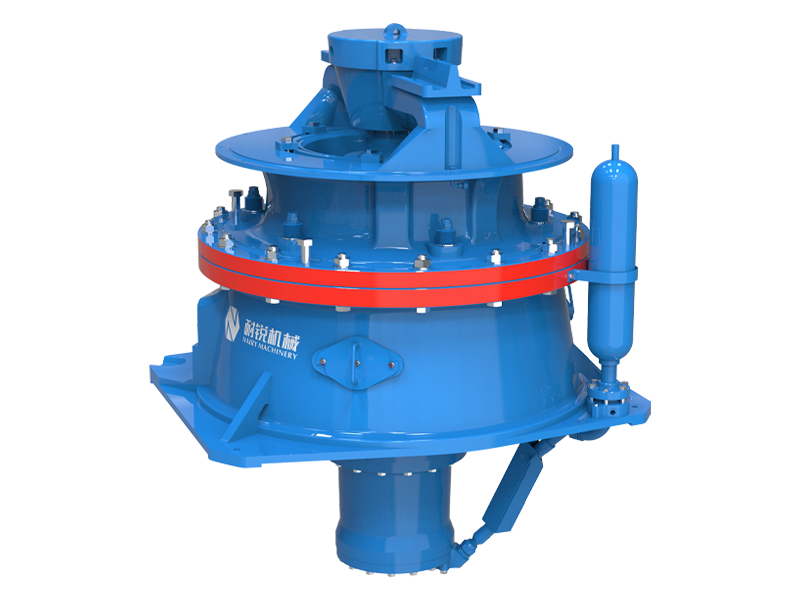

Single cylinder cone crusher

Category:

Product Description

NSH series single cylinder cone crusher is suitable for large and medium sand, ore processing enterprises. For secondary, tertiary or quaternary crushing of ore or rock.

01. wide application

01. wide application

Can crush hard rock. Chamber type can vary by replacing different lining plates , so as to adapt to various applications. Medium crushing type has a stable and large feed opening for the secondary crushing of materials.

02. Good product, good particle shape, solid productivity.

Can crush hard rock. Chamber type can vary by replacing different lining plates , so as to adapt to various applications. Medium crushing type has a stable and large feed opening for the secondary crushing of materials.

03. lower production cost

Optimized design of the crushing chamber and lining material makes the lining board more efficient. Positive pressure dust proof system can guarantee equipment clean, prolong the service life of lubricating oil, reduce manual maintenance costs. Most spare parts can bu dissembled on the upper and side of the equipment,which is safer,easier and more efficient.

04. Simple operation and maintenance

Optimized design of the crushing chamber and lining material makes the lining board more efficient. Positive pressure dust proof system can guarantee equipment clean, prolong the service life of lubricating oil, reduce manual maintenance costs. Most spare parts can bu dissembled on the upper and side of the equipment,which is safer,easier and more efficient.

05. High automation

The automatic control system can realize the functions of overload protection, over-iron protection and constant discharging in the crushing process.And also can realize the real-time monitoring of oil temperature, flow, pressure, load, discharge opening size and other parameters, to ensure reliable operation of the equipment.

06. Miner vibration, low noise

Running with the high precision spiral gear, lower noise, higher transmission efficiency and long service life.The vibration of the equipment is miner, and the overall steel frame with flexible support makes vibration to the foundation smaller, investment of foundation is lower accordingly.

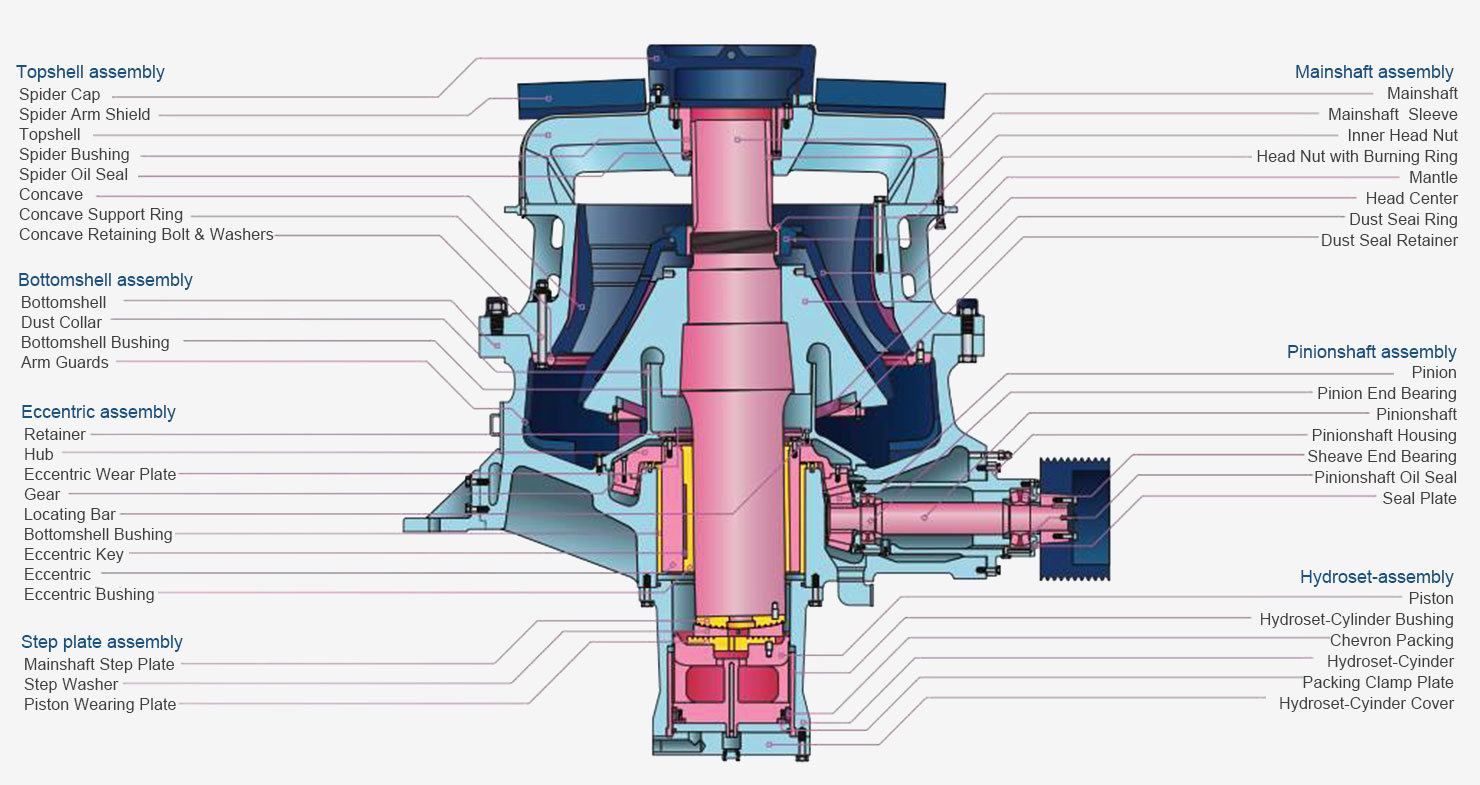

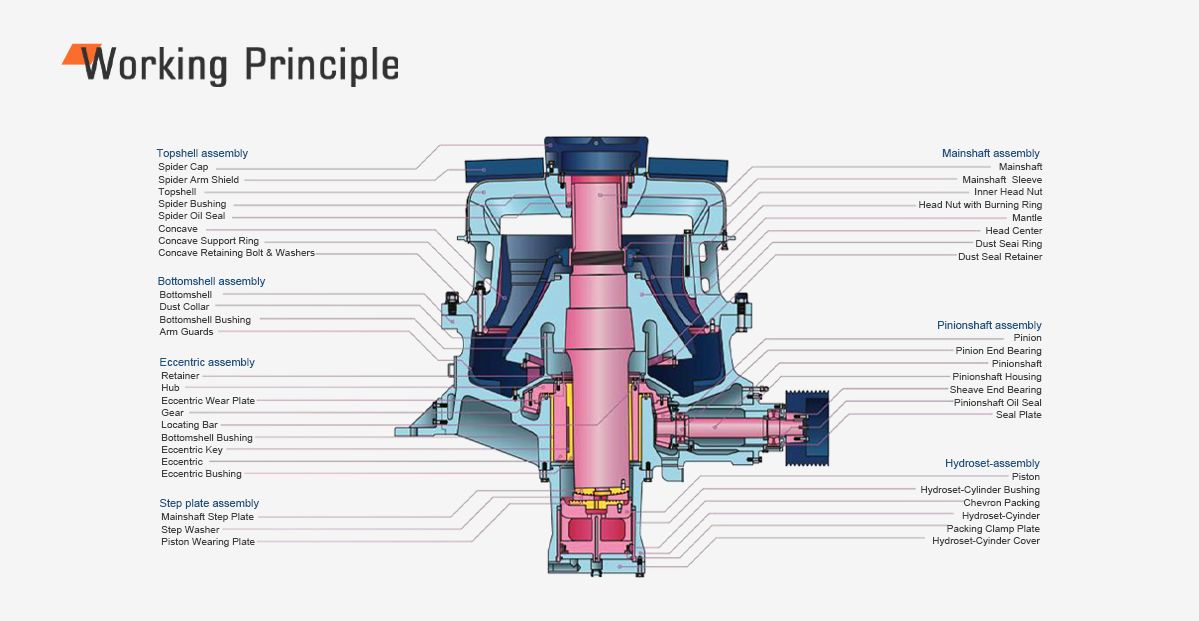

Single Cylinder Cone Crusher works, driven by the motor the transmission shaft rotates under the action of belt pulley and triangular belt. Next, the transmission shaft drives the eccentric sleeve to make it rotate around the axis.Meanwhile, the eccentric sleeve forces the movable cone to do pendular movement.This movement makes the movable cone and fixed cone sometimes close to sometimes far away from the rolling wall.Materials are continuously shocked squeezed and crushed in the crushing cavity between the crushing wall and the rolling wall. Finally materials are discharged out of the machine when their fineness reaches the discharging standard.

medium crushing

|

Model |

Installed Capacity(kw) |

Chamber |

Max.Feeding Size (mm) |

Capacity under CSS(t/h) |

||||||||||||||||

|

19mm |

22mm |

25mm |

29mm |

32mm |

35mm |

38mm |

41mm |

44mm |

48mm |

51mm |

54mm |

60mm |

64mm |

70mm |

76mm |

83mm |

||||

|

NSH90S |

90 |

EC |

240 |

102-118 |

108-144 |

115-158 |

121-168 |

127-145 |

132 |

|||||||||||

|

C |

200 |

82-110 |

87-116 |

92-128 |

98-113 |

103 |

||||||||||||||

|

NSH160S |

160 |

EC |

360 |

151 |

161-245 |

169-257 |

176-293 |

184-310 |

192-327 |

200-344 |

210-306 |

218-256 |

225 |

|||||||

|

C |

300 |

170-196 |

182-277 |

191-290 |

199-304 |

208-317 |

217-330 |

226-302 |

237 |

|||||||||||

|

MC |

235 |

130 |

137-209 |

147-224 |

154-235 |

161-245 |

168-261 |

175-275 |

182-244 |

192 |

||||||||||

|

NSH250S |

250 |

EC |

450 |

309-340 |

325-495 |

337-513 |

349-563 |

361-601 |

373-524 |

389-456 |

||||||||||

|

C |

400 |

331 |

344-523 |

362-551 |

375-571 |

389-515 |

402-467 |

415 |

||||||||||||

|

MC |

300 |

281 |

292-445 |

304-463 |

320-487 |

332-505 |

344-455 |

355-413 |

367 |

|||||||||||

|

NSH315S |

315 |

EC |

560 |

331-385 |

345-514 |

359-593 |

378-624 |

392-647 |

406-670 |

420-693 |

452-746 |

480-792 |

508-756 |

540 |

||||||

|

C |

500 |

335 |

350-464 |

364-602 |

379-626 |

399-658 |

413-683 |

428-707 |

458-755 |

477-710 |

507-589 |

|||||||||

fine crushing

|

Model |

Installed Capacity (kw) |

Chamber |

Max.Feeding Size (m) |

Capacity under CSS(t/h) |

|||||||||||||||

|

4mm |

6mm |

8mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

44mm |

51mm |

57mm |

64mm |

70mm |

||||

|

NSH90 |

90 |

EC |

155 |

55 |

59-90 |

64-97 |

69-104 |

73-111 |

78-118 |

89-128 |

|||||||||

|

C |

103 |

59-72 |

64-97 |

69-105 |

74-113 |

79-120 |

85-128 |

96 |

|||||||||||

|

M |

76 |

57-94 |

62-102 |

67-101 |

72-81 |

||||||||||||||

|

F |

42 |

27-34 |

29-50 |

31-54 |

32-57 |

35-48 |

37-42 |

||||||||||||

|

EF |

31 |

30-40t/h,80% is less than4.5-5.5mm |

|||||||||||||||||

|

NSH160 |

160 |

EC |

215 |

82-119 |

88-150 |

95-161 |

101-171 |

108-182 |

123-208 |

136-212 |

|||||||||

|

C |

168 |

81 |

88-143 |

95-155 |

102-166 |

109-177 |

116-189 |

132-215 |

146-176 |

||||||||||

|

M |

101 |

61 |

64-109 |

70-131 |

75-142 |

81-152 |

86-162 |

92-154 |

105-116 |

||||||||||

|

F |

62 |

42 |

48-78 |

51-83 |

54-88 |

59-96 |

63-103 |

68-105 |

72-95 |

77 |

|||||||||

|

EF |

42 |

70-105t/h,Of which, 80% is less than 4.5-5.5mm |

|||||||||||||||||

|

NSH250 |

250 |

EC |

250 |

112-155 |

121-214 |

129-276 |

138-294 |

147-313 |

168-357 |

185-395 |

203-384 |

||||||||

|

C |

204 |

108-137 |

117-223 |

126-292 |

134-312 |

143-332 |

163-378 |

180-335 |

197-229 |

||||||||||

|

M |

124 |

125-206 |

135-278 |

145-298 |

154-318 |

164-339 |

187-284 |

207-234 |

|||||||||||

|

F |

83 |

90-135 |

96-176 |

104-191 |

112-206 |

120-221 |

129-236 |

137-251 |

156-208 |

||||||||||

|

EF |

47 |

100-125t/h,80% is less than 6.0-7.5mm |

|||||||||||||||||

|

NSH315 |

315 |

EC |

321 |

190-338 |

203-436 |

216-464 |

246-547 |

272-605 |

298-662 |

328-511 |

|||||||||

|

C |

253 |

219-231 |

235-379 |

251-480 |

267-510 |

305-582 |

337-643 |

369-635 |

406-519 |

||||||||||

|

M |

155 |

203-326 |

217-440 |

232-470 |

247-500 |

282-532 |

311-536 |

||||||||||||

|

F |

96 |

195-304 |

210-328 |

225-352 |

241-376 |

256-400 |

224-423 |

248-399 |

|||||||||||

|

EF |

62 |

110-116 |

116-220 |

211-293 |

227-316 |

244-298 |

261-290 |

166-213 |

|||||||||||

|

NSH500 |

500 |

EC |

315 |

326 |

350-527 |

374-632 |

398-725 |

454-803 |

501-898 |

549-985 |

604-1071 |

||||||||

|

C |

263 |

344-548 |

368-653 |

390-749 |

447-836 |

492-933 |

535-1022 |

596-1126 |

|||||||||||

|

M |

152 |

289-675 |

310-541 |

331-632 |

353-710 |

401-768 |

444-859 |

486-943 |

536-1036 |

||||||||||

|

F |

97 |

189-416 |

205-479 |

221-549 |

238-585 |

254-621 |

270-680 |

308-554 |

340-476 |

373 |

|||||||||

|

EF |

72 |

168-393 |

183-425 |

196-459 |

211-493 |

225-526 |

240-560 |

274-493 |

303-424 |

331 |

|||||||||

|

NSH600 |

600 |

EC |

350 |

477-849 |

544-968 |

601-1070 |

658-1172 |

725-1291 |

782-1393 |

849-1512 |

806-1331 |

||||||||

|

C |

287 |

483-806 |

511-893 |

525-1018 |

581-1125 |

636-1232 |

700-1357 |

756-1464 |

820-1461 |

776-1286 |

|||||||||

|

M |

184 |

432-733 |

468-786 |

495-836 |

519-953 |

533-1054 |

558-1154 |

592-1271 |

686-1372 |

710-1248 |

705-1098 |

||||||||

|

F |

99 |

357-595 |

385-656 |

414-704 |

442-752 |

470-800 |

495-912 |

517-857 |

529-788 |

||||||||||

|

EF |

88 |

290-505 |

304-517 |

328-558 |

353-598 |

376-639 |

405-710 |

455-775 |

503-728 |

511-669 |

|||||||||

|

NSH750 |

750 |

EC |

428 |

594-859 |

649-1309 |

696-1446 |

743-1548 |

798-1745 |

846-1883 |

801-2043 |

748-2181 |

||||||||

|

C |

382 |

697 |

622-974 |

682-1404 |

732-1552 |

783-1700 |

842-1873 |

893-2020 |

952-2193 |

812-2140 |

|||||||||

|

M |

219 |

567-812 |

587-970 |

607-1051 |

626-1106 |

672-1261 |

701-1394 |

750-1526 |

796-1681 |

735-1814 |

780-1800 |

720-1561 |

|||||||

|

F |

139 |

248-789 |

468-839 |

487-864 |

507-935 |

537-997 |

486-1142 |

513-1207 |

592-1277 |

667-1458 |

705-1256 |

||||||||

Remarks: The above data is for reference only, as the production capacity of the crusher is affected by crushing ratio of the selected equipment, material hardness, feeding particle size composition, cycle load, water content in the feed, mud content, etc. For details,please consult our engineers.

NSH series single cylinder cone crusher is suitable for large and medium sand, ore processing enterprises. For secondary, tertiary or quaternary crushing of ore or rock.

01. wide application

01. wide application

Can crush hard rock. Chamber type can vary by replacing different lining plates , so as to adapt to various applications. Medium crushing type has a stable and large feed opening for the secondary crushing of materials.

02. Good product, good particle shape, solid productivity.

Can crush hard rock. Chamber type can vary by replacing different lining plates , so as to adapt to various applications. Medium crushing type has a stable and large feed opening for the secondary crushing of materials.

03. lower production cost

Optimized design of the crushing chamber and lining material makes the lining board more efficient. Positive pressure dust proof system can guarantee equipment clean, prolong the service life of lubricating oil, reduce manual maintenance costs. Most spare parts can bu dissembled on the upper and side of the equipment,which is safer,easier and more efficient.

04. Simple operation and maintenance

Optimized design of the crushing chamber and lining material makes the lining board more efficient. Positive pressure dust proof system can guarantee equipment clean, prolong the service life of lubricating oil, reduce manual maintenance costs. Most spare parts can bu dissembled on the upper and side of the equipment,which is safer,easier and more efficient.

05. High automation

The automatic control system can realize the functions of overload protection, over-iron protection and constant discharging in the crushing process.And also can realize the real-time monitoring of oil temperature, flow, pressure, load, discharge opening size and other parameters, to ensure reliable operation of the equipment.

06. Miner vibration, low noise

Running with the high precision spiral gear, lower noise, higher transmission efficiency and long service life.The vibration of the equipment is miner, and the overall steel frame with flexible support makes vibration to the foundation smaller, investment of foundation is lower accordingly.

Single Cylinder Cone Crusher works, driven by the motor the transmission shaft rotates under the action of belt pulley and triangular belt. Next, the transmission shaft drives the eccentric sleeve to make it rotate around the axis.Meanwhile, the eccentric sleeve forces the movable cone to do pendular movement.This movement makes the movable cone and fixed cone sometimes close to sometimes far away from the rolling wall.Materials are continuously shocked squeezed and crushed in the crushing cavity between the crushing wall and the rolling wall. Finally materials are discharged out of the machine when their fineness reaches the discharging standard.

medium crushing

|

Model |

Installed Capacity(kw) |

Chamber |

Max.Feeding Size (mm) |

Capacity under CSS(t/h) |

||||||||||||||||

|

19mm |

22mm |

25mm |

29mm |

32mm |

35mm |

38mm |

41mm |

44mm |

48mm |

51mm |

54mm |

60mm |

64mm |

70mm |

76mm |

83mm |

||||

|

NSH90S |

90 |

EC |

240 |

102-118 |

108-144 |

115-158 |

121-168 |

127-145 |

132 |

|||||||||||

|

C |

200 |

82-110 |

87-116 |

92-128 |

98-113 |

103 |

||||||||||||||

|

NSH160S |

160 |

EC |

360 |

151 |

161-245 |

169-257 |

176-293 |

184-310 |

192-327 |

200-344 |

210-306 |

218-256 |

225 |

|||||||

|

C |

300 |

170-196 |

182-277 |

191-290 |

199-304 |

208-317 |

217-330 |

226-302 |

237 |

|||||||||||

|

MC |

235 |

130 |

137-209 |

147-224 |

154-235 |

161-245 |

168-261 |

175-275 |

182-244 |

192 |

||||||||||

|

NSH250S |

250 |

EC |

450 |

309-340 |

325-495 |

337-513 |

349-563 |

361-601 |

373-524 |

389-456 |

||||||||||

|

C |

400 |

331 |

344-523 |

362-551 |

375-571 |

389-515 |

402-467 |

415 |

||||||||||||

|

MC |

300 |

281 |

292-445 |

304-463 |

320-487 |

332-505 |

344-455 |

355-413 |

367 |

|||||||||||

|

NSH315S |

315 |

EC |

560 |

331-385 |

345-514 |

359-593 |

378-624 |

392-647 |

406-670 |

420-693 |

452-746 |

480-792 |

508-756 |

540 |

||||||

|

C |

500 |

335 |

350-464 |

364-602 |

379-626 |

399-658 |

413-683 |

428-707 |

458-755 |

477-710 |

507-589 |

|||||||||

fine crushing

|

Model |

Installed Capacity (kw) |

Chamber |

Max.Feeding Size (m) |

Capacity under CSS(t/h) |

|||||||||||||||

|

4mm |

6mm |

8mm |

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

44mm |

51mm |

57mm |

64mm |

70mm |

||||

|

NSH90 |

90 |

EC |

155 |

55 |

59-90 |

64-97 |

69-104 |

73-111 |

78-118 |

89-128 |

|||||||||

|

C |

103 |

59-72 |

64-97 |

69-105 |

74-113 |

79-120 |

85-128 |

96 |

|||||||||||

|

M |

76 |

57-94 |

62-102 |

67-101 |

72-81 |

||||||||||||||

|

F |

42 |

27-34 |

29-50 |

31-54 |

32-57 |

35-48 |

37-42 |

||||||||||||

|

EF |

31 |

30-40t/h,80% is less than4.5-5.5mm |

|||||||||||||||||

|

NSH160 |

160 |

EC |

215 |

82-119 |

88-150 |

95-161 |

101-171 |

108-182 |

123-208 |

136-212 |

|||||||||

|

C |

168 |

81 |

88-143 |

95-155 |

102-166 |

109-177 |

116-189 |

132-215 |

146-176 |

||||||||||

|

M |

101 |

61 |

64-109 |

70-131 |

75-142 |

81-152 |

86-162 |

92-154 |

105-116 |

||||||||||

|

F |

62 |

42 |

48-78 |

51-83 |

54-88 |

59-96 |

63-103 |

68-105 |

72-95 |

77 |

|||||||||

|

EF |

42 |

70-105t/h,Of which, 80% is less than 4.5-5.5mm |

|||||||||||||||||

|

NSH250 |

250 |

EC |

250 |

112-155 |

121-214 |

129-276 |

138-294 |

147-313 |

168-357 |

185-395 |

203-384 |

||||||||

|

C |

204 |

108-137 |

117-223 |

126-292 |

134-312 |

143-332 |

163-378 |

180-335 |

197-229 |

||||||||||

|

M |

124 |

125-206 |

135-278 |

145-298 |

154-318 |

164-339 |

187-284 |

207-234 |

|||||||||||

|

F |

83 |

90-135 |

96-176 |

104-191 |

112-206 |

120-221 |

129-236 |

137-251 |

156-208 |

||||||||||

|

EF |

47 |

100-125t/h,80% is less than 6.0-7.5mm |

|||||||||||||||||

|

NSH315 |

315 |

EC |

321 |

190-338 |

203-436 |

216-464 |

246-547 |

272-605 |

298-662 |

328-511 |

|||||||||

|

C |

253 |

219-231 |

235-379 |

251-480 |

267-510 |

305-582 |

337-643 |

369-635 |

406-519 |

||||||||||

|

M |

155 |

203-326 |

217-440 |

232-470 |

247-500 |

282-532 |

311-536 |

||||||||||||

|

F |

96 |

195-304 |

210-328 |

225-352 |

241-376 |

256-400 |

224-423 |

248-399 |

|||||||||||

|

EF |

62 |

110-116 |

116-220 |

211-293 |

227-316 |

244-298 |

261-290 |

166-213 |

|||||||||||

|

NSH500 |

500 |

EC |

315 |

326 |

350-527 |

374-632 |

398-725 |

454-803 |

501-898 |

549-985 |

604-1071 |

||||||||

|

C |

263 |

344-548 |

368-653 |

390-749 |

447-836 |

492-933 |

535-1022 |

596-1126 |

|||||||||||

|

M |

152 |

289-675 |

310-541 |

331-632 |

353-710 |

401-768 |

444-859 |

486-943 |

536-1036 |

||||||||||

|

F |

97 |

189-416 |

205-479 |

221-549 |

238-585 |

254-621 |

270-680 |

308-554 |

340-476 |

373 |

|||||||||

|

EF |

72 |

168-393 |

183-425 |

196-459 |

211-493 |

225-526 |

240-560 |

274-493 |

303-424 |

331 |

|||||||||

|

NSH600 |

600 |

EC |

350 |

477-849 |

544-968 |

601-1070 |

658-1172 |

725-1291 |

782-1393 |

849-1512 |

806-1331 |

||||||||

|

C |

287 |

483-806 |

511-893 |

525-1018 |

581-1125 |

636-1232 |

700-1357 |

756-1464 |

820-1461 |

776-1286 |

|||||||||

|

M |

184 |

432-733 |

468-786 |

495-836 |

519-953 |

533-1054 |

558-1154 |

592-1271 |

686-1372 |

710-1248 |

705-1098 |

||||||||

|

F |

99 |

357-595 |

385-656 |

414-704 |

442-752 |

470-800 |

495-912 |

517-857 |

529-788 |

||||||||||

|

EF |

88 |

290-505 |

304-517 |

328-558 |

353-598 |

376-639 |

405-710 |

455-775 |

503-728 |

511-669 |

|||||||||

|

NSH750 |

750 |

EC |

428 |

594-859 |

649-1309 |

696-1446 |

743-1548 |

798-1745 |

846-1883 |

801-2043 |

748-2181 |

||||||||

|

C |

382 |

697 |

622-974 |

682-1404 |

732-1552 |

783-1700 |

842-1873 |

893-2020 |

952-2193 |

812-2140 |

|||||||||

|

M |

219 |

567-812 |

587-970 |

607-1051 |

626-1106 |

672-1261 |

701-1394 |

750-1526 |

796-1681 |

735-1814 |

780-1800 |

720-1561 |

|||||||

|

F |

139 |

248-789 |

468-839 |

487-864 |

507-935 |

537-997 |

486-1142 |

513-1207 |

592-1277 |

667-1458 |

705-1256 |

||||||||

Remarks: The above data is for reference only, as the production capacity of the crusher is affected by crushing ratio of the selected equipment, material hardness, feeding particle size composition, cycle load, water content in the feed, mud content, etc. For details,please consult our engineers.

Previous:

Key words:

Product Description

Particle Size Curve

Message

Related products