Products

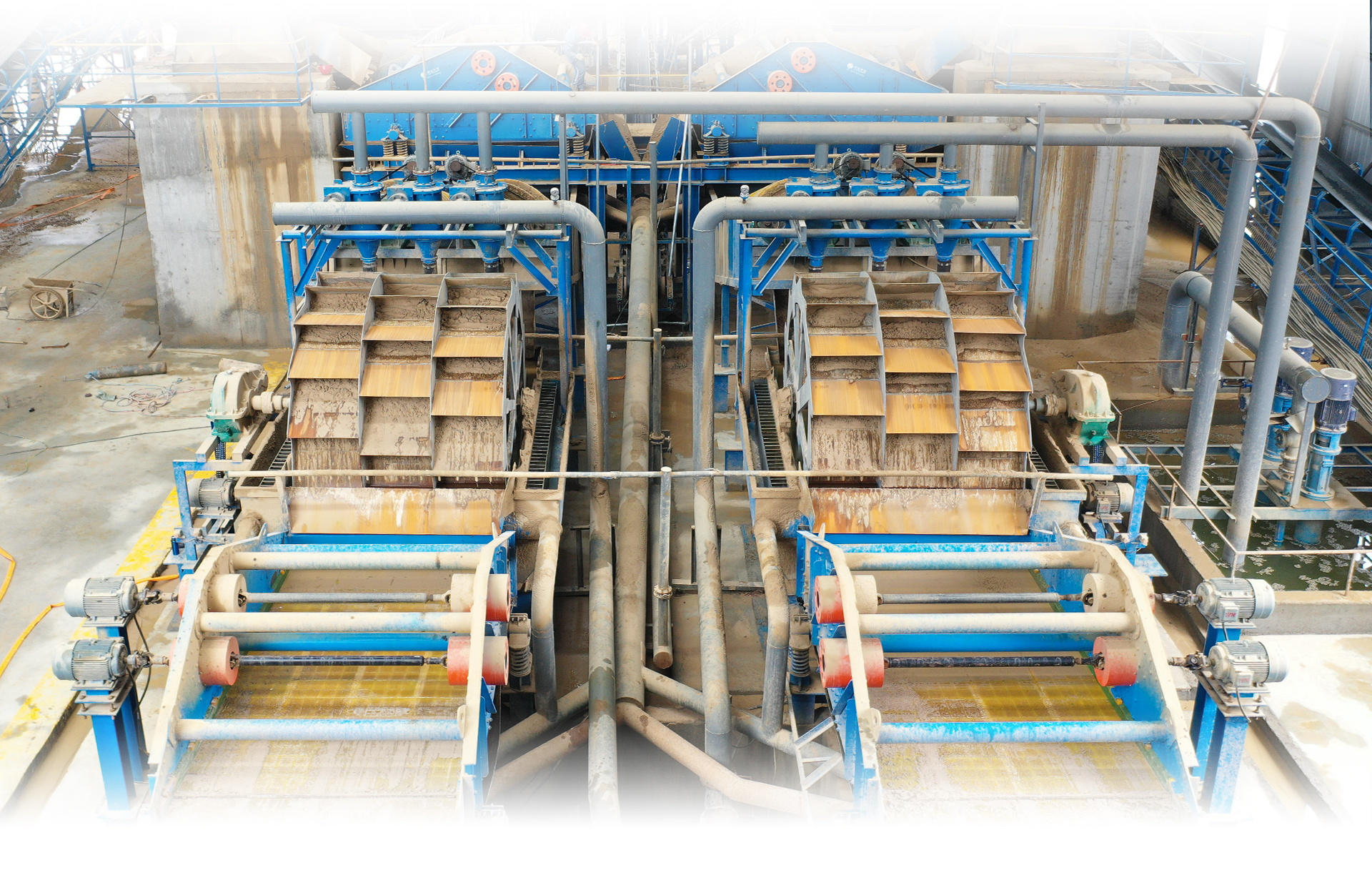

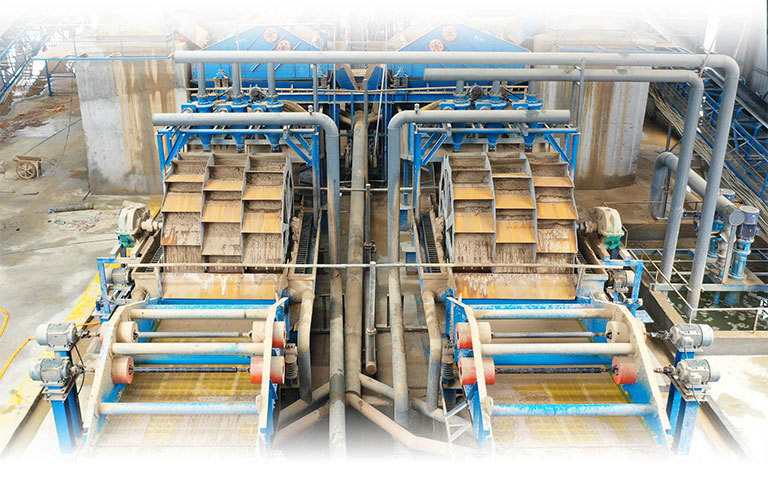

Wheel sand washer

Category:

Product Description

DX series wheel sand washer is a new structure sand washing equipment developed by Nairy in combination with the operation of sand and gravel industry at home and abroad and years of practical experiences. The machine is widely used in sand washing operations in the sand aggregate processing industry, which can effectively wash away the mixed stone powder and impurities in the sand and improve sand quality.

DX series wheel sand washer is a new structure sand washing equipment developed by Nairy in combination with the operation of sand and gravel industry at home and abroad and years of practical experiences. The machine is widely used in sand washing operations in the sand aggregate processing industry, which can effectively wash away the mixed stone powder and impurities in the sand and improve sand quality.

●High recovery rate of fine sand, reasonable product configuration, less sludge content, and large single-machine processing capacity.

●Manganese steel (or 304 stainless steel) punched strip seam screen, wear-resistant high aluminum ceramic combination design of the discharge port ensures the reliability of long-term operation of the equipment.

●Scientific mesh structure design improves the cleanliness of sand washing.

●The design of the tank adopts the unique overflow drainage structure design of Nairy, which solves the problem of fine sand loss caused by turbulence during the operation of sand washing.Increased residence time of fine sand in the tank body, guaranteed the classification efficiency, and improved the recovery rate of fine sand.

●The tank body and parts which might be seriously worn are sprayed with imported wear-resistant materials to ensure at least 5 years free from corrosion and rust.

●The bearing brand includes ZSZ or SKF, NSK, and the motor is selected from well-known domestic brands or SIEMENS, WEG to ensure the long-term reliable operation of the equipment.

|

Model |

Feed particle size (mm) |

Recovered particle size (mm) |

Processing capacity (t/h) |

Power (kw) |

|

DX3015 |

≤10 |

>0.16 |

50-100 |

5.5 |

|

DX3620 |

≤10 |

>0.16 |

100-150 |

7.5 |

|

DX3624 |

≤10 |

>0.16 |

120-200 |

11 |

|

DX4230 |

≤10 |

>0.16 |

150-250 |

15 |

DX series wheel sand washer is a new structure sand washing equipment developed by Nairy in combination with the operation of sand and gravel industry at home and abroad and years of practical experiences. The machine is widely used in sand washing operations in the sand aggregate processing industry, which can effectively wash away the mixed stone powder and impurities in the sand and improve sand quality.

●High recovery rate of fine sand, reasonable product configuration, less sludge content, and large single-machine processing capacity.

●Manganese steel (or 304 stainless steel) punched strip seam screen, wear-resistant high aluminum ceramic combination design of the discharge port ensures the reliability of long-term operation of the equipment.

●Scientific mesh structure design improves the cleanliness of sand washing.

●The design of the tank adopts the unique overflow drainage structure design of Nairy, which solves the problem of fine sand loss caused by turbulence during the operation of sand washing.Increased residence time of fine sand in the tank body, guaranteed the classification efficiency, and improved the recovery rate of fine sand.

●The tank body and parts which might be seriously worn are sprayed with imported wear-resistant materials to ensure at least 5 years free from corrosion and rust.

●The bearing brand includes ZSZ or SKF, NSK, and the motor is selected from well-known domestic brands or SIEMENS, WEG to ensure the long-term reliable operation of the equipment.

|

Model |

Feed particle size (mm) |

Recovered particle size (mm) |

Processing capacity (t/h) |

Power (kw) |

|

DX3015 |

≤10 |

>0.16 |

50-100 |

5.5 |

|

DX3620 |

≤10 |

>0.16 |

100-150 |

7.5 |

|

DX3624 |

≤10 |

>0.16 |

120-200 |

11 |

|

DX4230 |

≤10 |

>0.16 |

150-250 |

15 |

Previous:

Next:

Key words:

Product Brief

Product Features

Message

Related products