Products

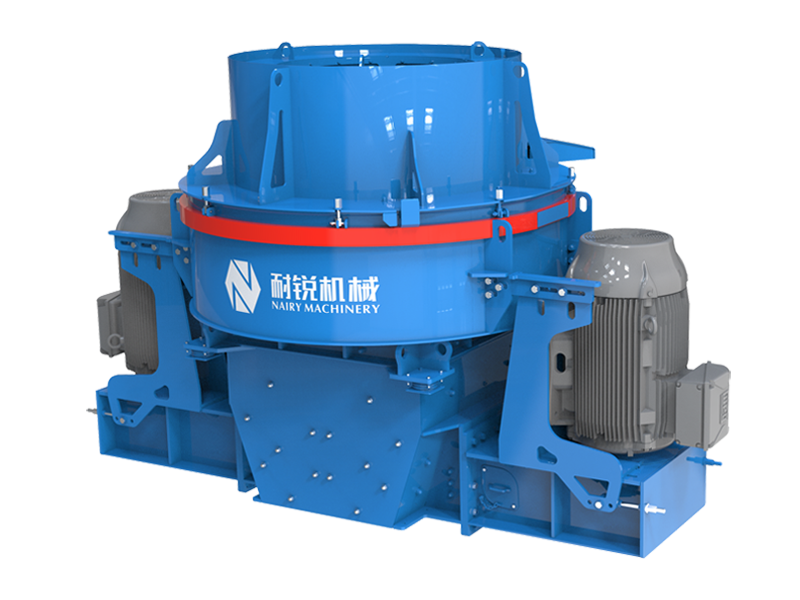

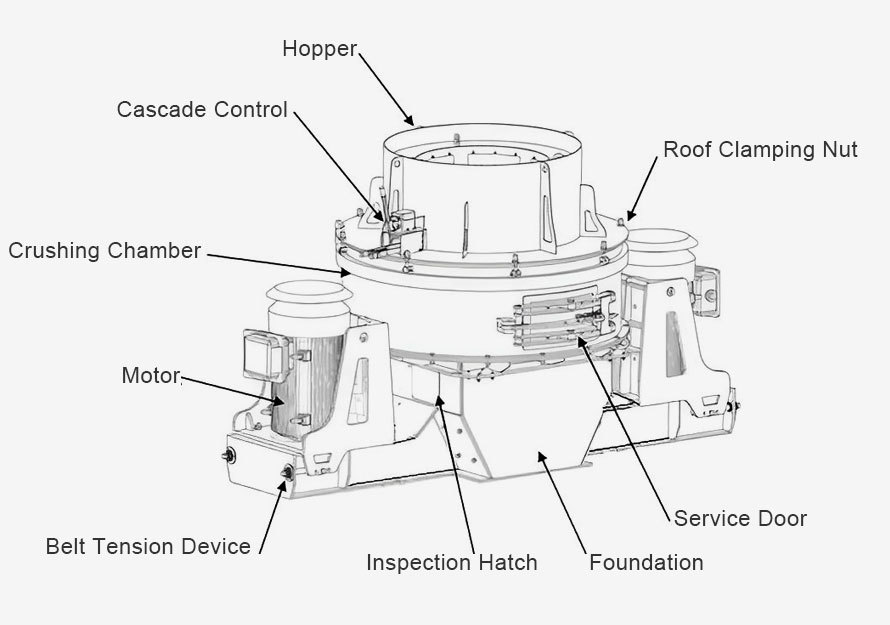

Vertical shaft impact crusher

Category:

Product Description

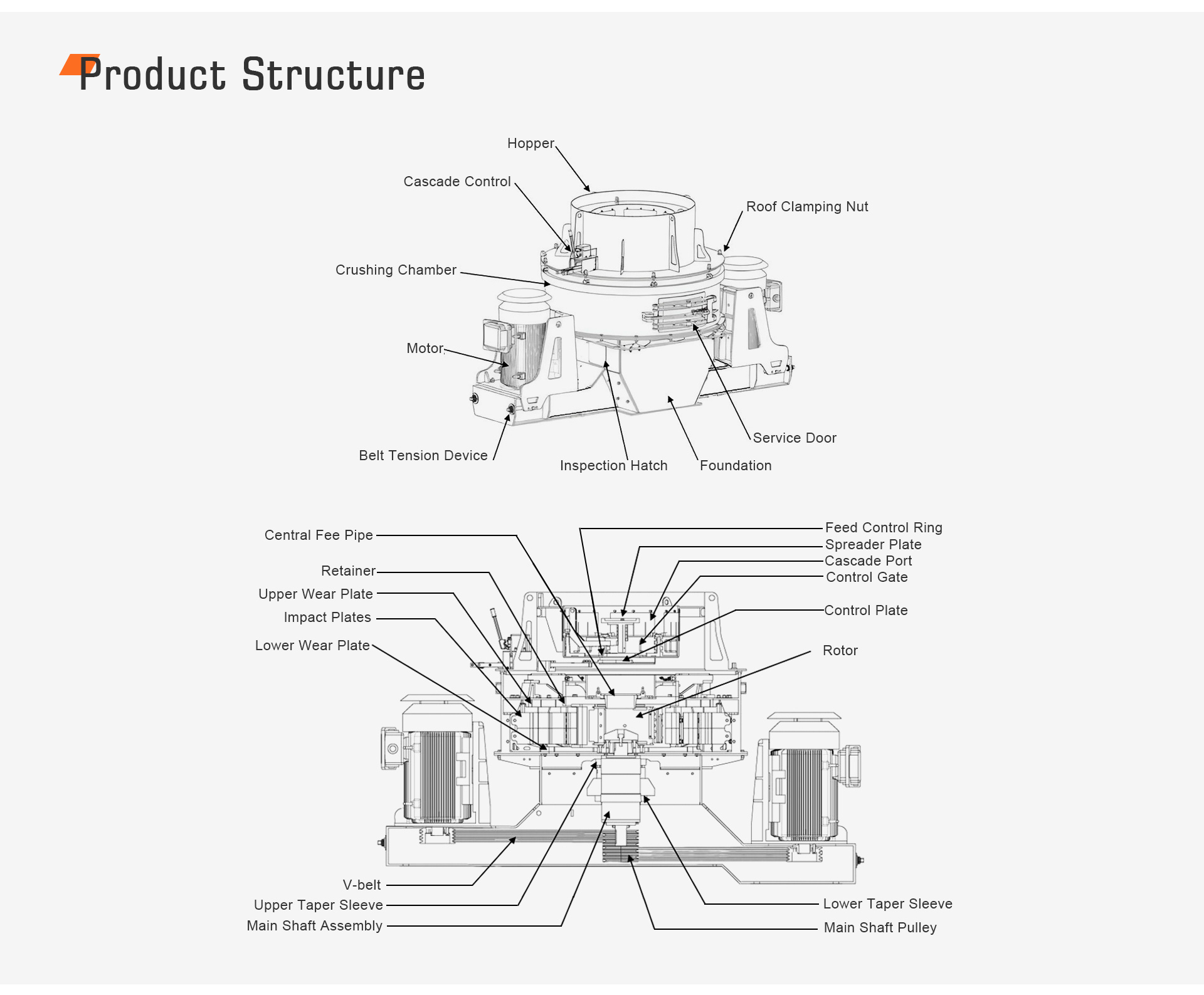

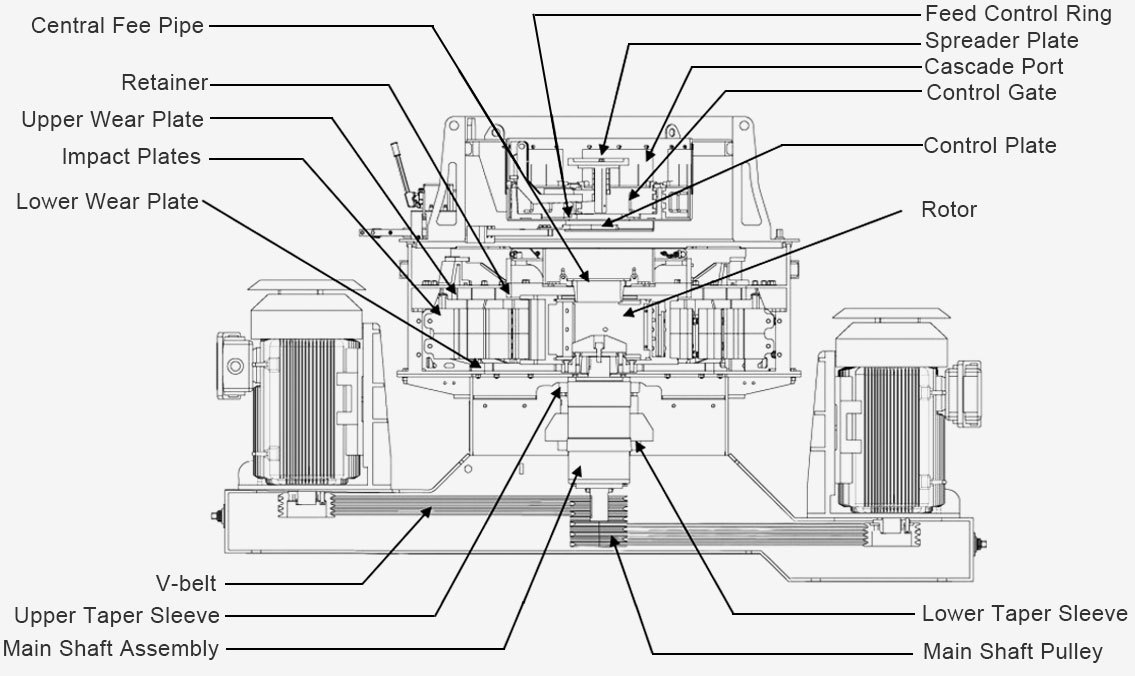

The NVS series vertical shaft impact crusher crush rocks by the inter-impact of rocks fed into the crusher. In today's market, this self-crushing process produces aggregates with the best granular shape. The NVS series' high-speed impact crushing improves rock compactness and improved particle shape, resulting in high-quality products at the lowest cost while reducing product moisture and facilitating screening. This equipment machine has two kinds of crushing chambers: "stone hit stone" and "stone hit iron", "stone hit stone" is mostly used in the crushing processing and production of hard materials, which sand rate over 40%, "stone hit iron" is mostly used in the crushing and processing of medium and hard materials, with sand production rate over 60%, and the two chamber structures can be converted to each other to adapt to crushing processing of different material.

|

01. Feed Control Device The equipment can optionally be equipped with a manual hydraulic pump to adjust the flow rate of the impeller feed, and at the same time adjustment of high and low position of the distributor,it can accurately control in coordination with ratio of rotor feed and waterfall overflow.

|

02. Top Hydraulic Lifting and Opening Rotation DeviceThe upper cover of the equipment can be configured with a hydraulic top opening lifting device, to facilitate, feeding hopper jacking , rotating, and removal during equipment overhaul. |

|

|

|

|

Specifications |

Maximum Feeding Size (mm) |

Throughput (t/h) |

Power (kw) |

Drive Mode |

|

NVS8418 |

50 |

125-156 |

2×90 |

Dual-motor |

|

NVS8422 |

150-198 |

2×110 |

Dual-motor |

|

|

NVS8426 |

175-244 |

2×132 |

Dual-motor |

|

|

NVS8432 |

200-310 |

2×160 |

Dual-motor |

|

|

NVS9944 |

60 |

315-385 |

2×220 |

Dual-motor |

|

NVS9950 |

320-440 |

2×250 |

Dual-motor |

|

|

NVS9963 |

420-560 |

2×315 |

Dual-motor |

The NVS series vertical shaft impact crusher crush rocks by the inter-impact of rocks fed into the crusher. In today's market, this self-crushing process produces aggregates with the best granular shape. The NVS series' high-speed impact crushing improves rock compactness and improved particle shape, resulting in high-quality products at the lowest cost while reducing product moisture and facilitating screening. This equipment machine has two kinds of crushing chambers: "stone hit stone" and "stone hit iron", "stone hit stone" is mostly used in the crushing processing and production of hard materials, which sand rate over 40%, "stone hit iron" is mostly used in the crushing and processing of medium and hard materials, with sand production rate over 60%, and the two chamber structures can be converted to each other to adapt to crushing processing of different material.

01. Feed Control Device

The equipment can optionally be equipped with a manual hydraulic pump to adjust the flow rate of the impeller feed, and at the same time adjustment of high and low position of the distributor,it can accurately control in coordination with ratio of rotor feed and waterfall overflow.

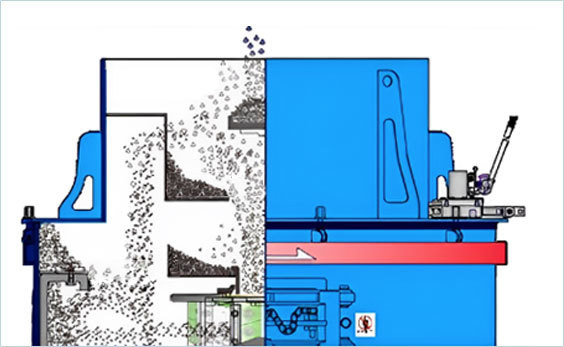

02. Top Hydraulic Lifting and Opening Rotation Device

The upper cover of the equipment can be configured with a hydraulic top opening lifting device, to facilitate, feeding hopper jacking , rotating, and removal during equipment overhaul.

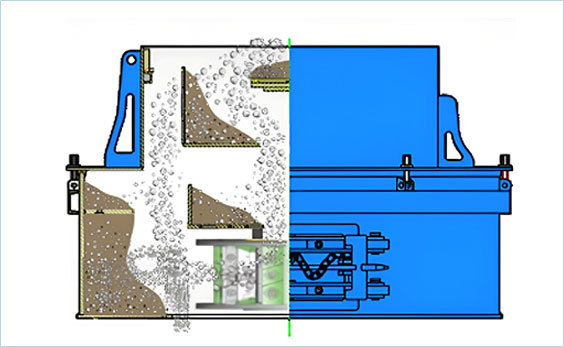

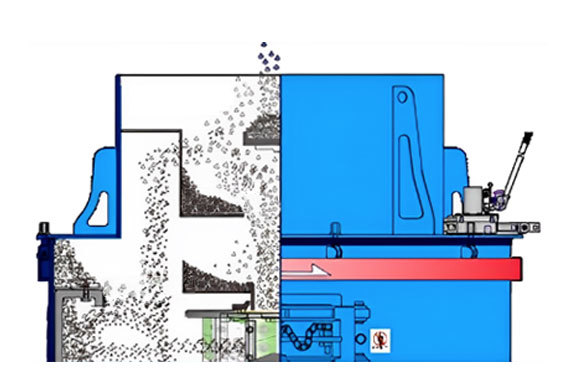

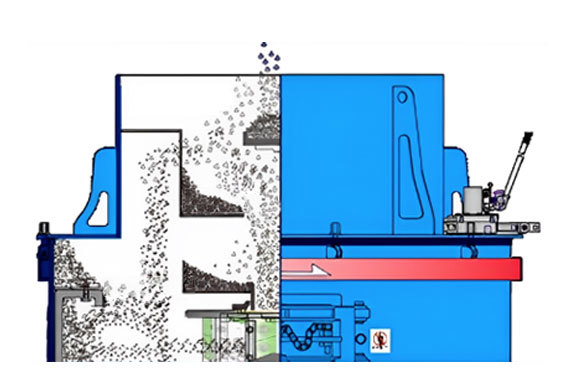

03. Stone-hit-stone Crushing Chamber

The materials fall evenly and vertically from the upper part of the equipment, part of it enters the chamber the rest enters high-speed rotating rotor chamber through feeding barrel and then ejected from the launch port of the rotor under the action of high-speed centrifugal force, and falls from the material distribution window on the rotor circle. The material is crushed by the high-speed collision of each other, and after the collision experience,material will form eddy currents and multiple collisions and frictions in the rotor and crushing chamber.

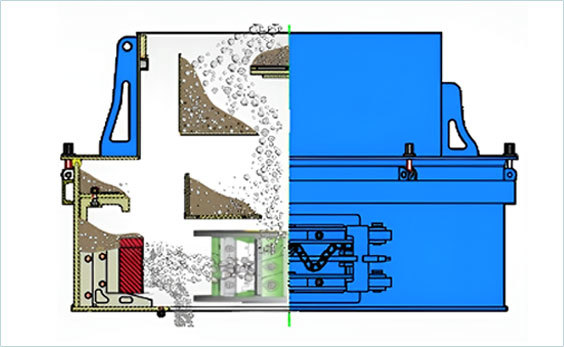

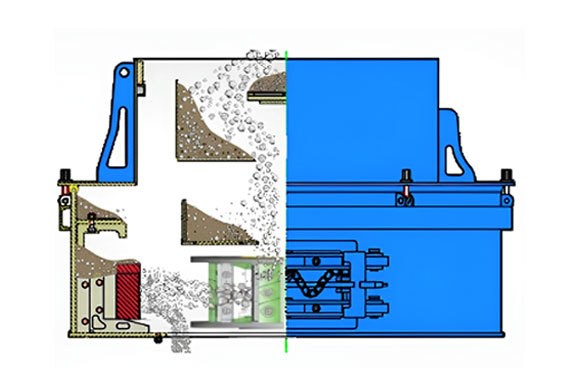

04. Stone-hit Iron Crushing Chamber

The material falls evenly and vertically from the upper part of the equipment, enters the high-speed rotating rotor chamber through the feeding barrel, and is ejected from the launching port of the rotor at high speed under the action of centrifugal force, and colliding with the anvil or counter-attack plate around the rotor circle at high speed.

|

Specifications |

Maximum Feeding Size (mm) |

Throughput (t/h) |

Power (kw) |

Drive Mode |

|

NVS8418 |

50 |

125-156 |

2×90 |

Dual-motor |

|

NVS8422 |

150-198 |

2×110 |

Dual-motor |

|

|

NVS8426 |

175-244 |

2×132 |

Dual-motor |

|

|

NVS8432 |

200-310 |

2×160 |

Dual-motor |

|

|

NVS9944 |

60 |

315-385 |

2×220 |

Dual-motor |

|

NVS9950 |

320-440 |

2×250 |

Dual-motor |

|

|

NVS9963 |

420-560 |

2×315 |

Dual-motor |

Next:

Key words:

Product description

Technical Parameters

Specifications

Message

Related products