Products

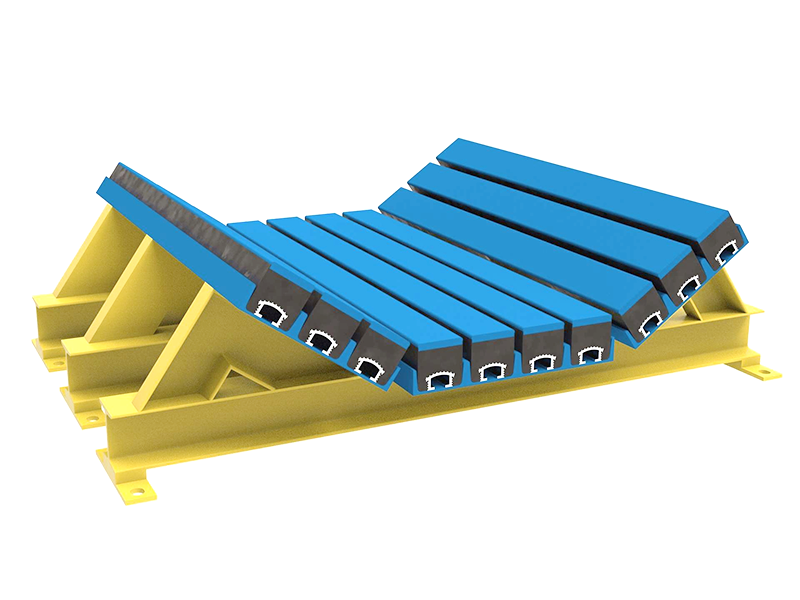

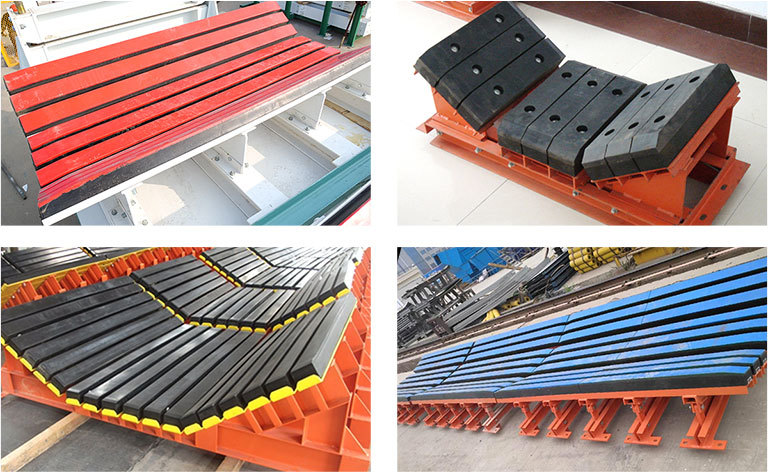

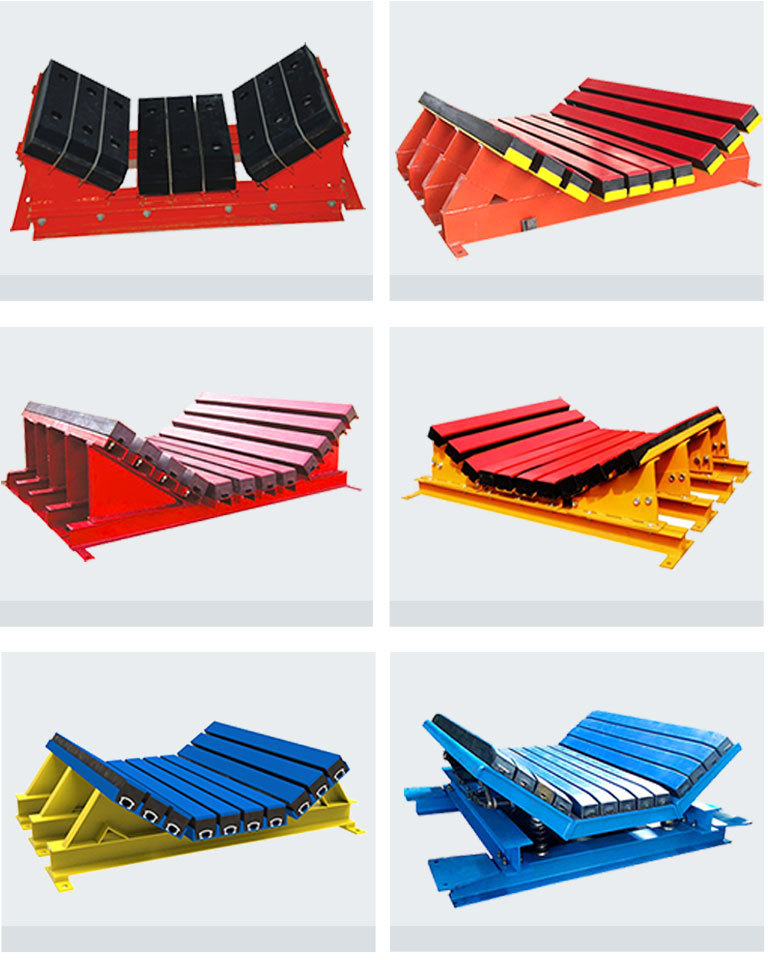

Impact bed

Category:

Product Description

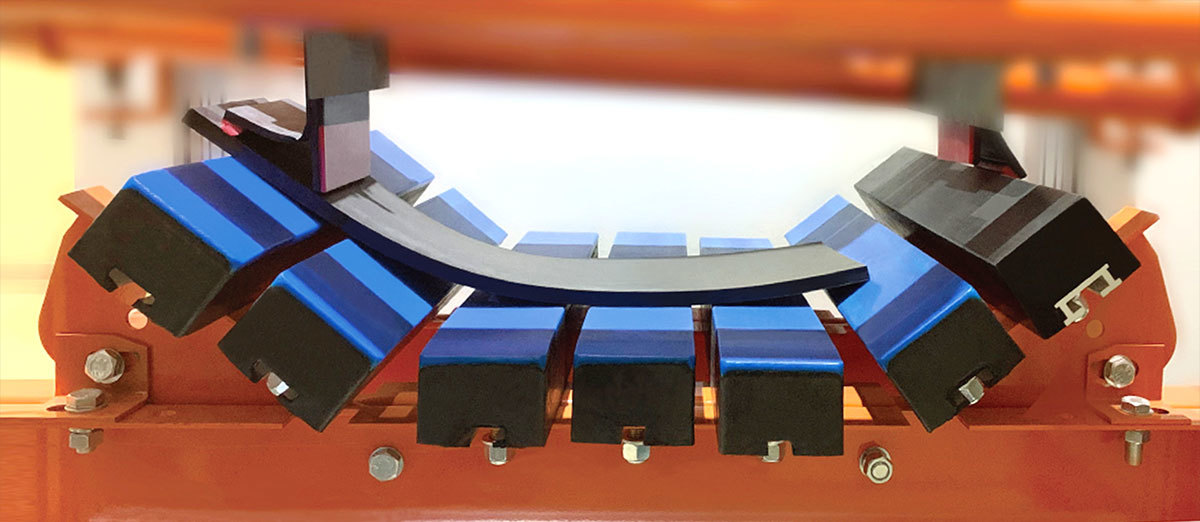

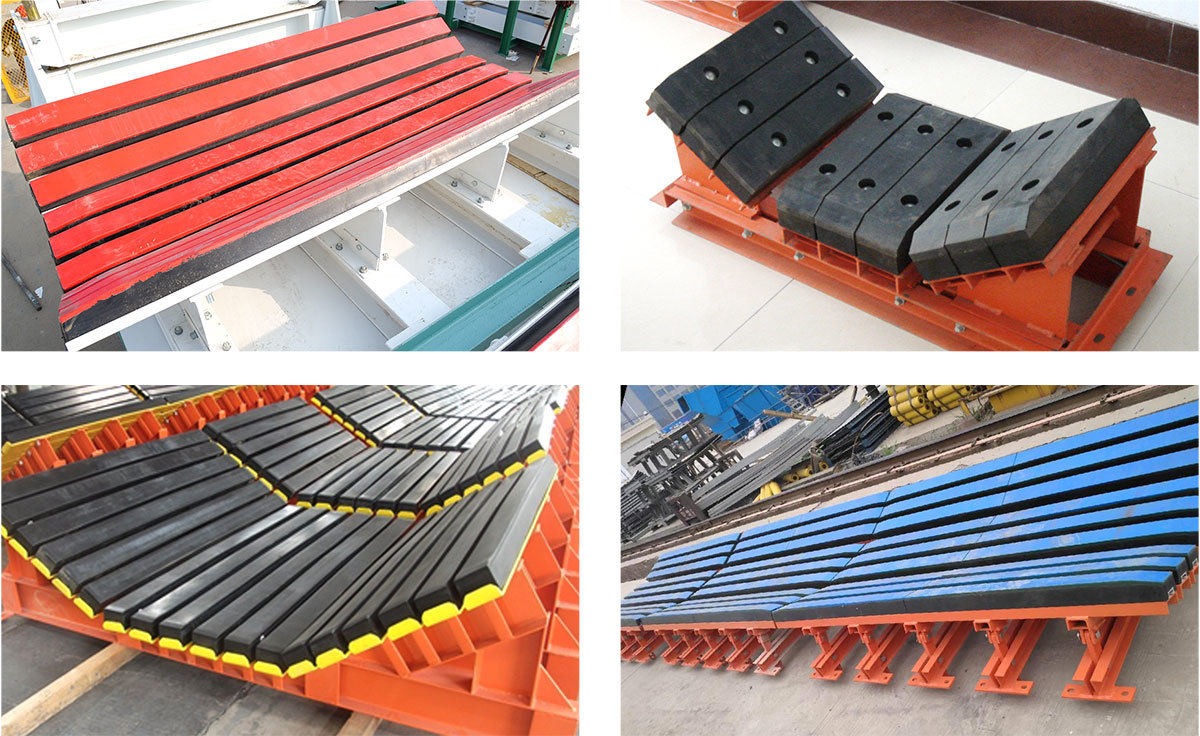

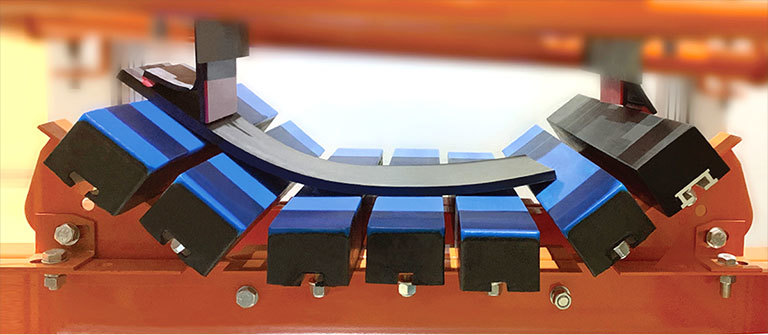

Impact Bars&Bed is used for vibration damping protection of conveyor belt at material loading blanking point. The impact bed is mainly designed to instead of impact idler, impact bed consists of impact bar, the impact bar is made of high elasticity special rubber,which can absorb the impact force effectively when the material dropping, greatly reduce the impact to the conveyor belt and improved the stress state of the loading point. Special UHMW used in the impact bar surface, which greatly reduce the coefficient of friction between belt and impact bar and has good features of wear resistant. To the conveyor belt, the application of the impact bed ensures stress uniform, effectively prevent belt longitudinal tear due to the idler roller fracture or fall off to extend its life.

ADVANCEMENTS

① Low friction coefficient UHMWPE engineered plastic impact block;

② Avoid belt damage by supporting it effectively;

③ Avoid splash back of the material;

④ Only need to change the impact block reducing maintenance costs;

⑤ Designed as a whole mould which is more convenient to assemble and maintain;

⑥ Easy to transform and make a better work efficiency;

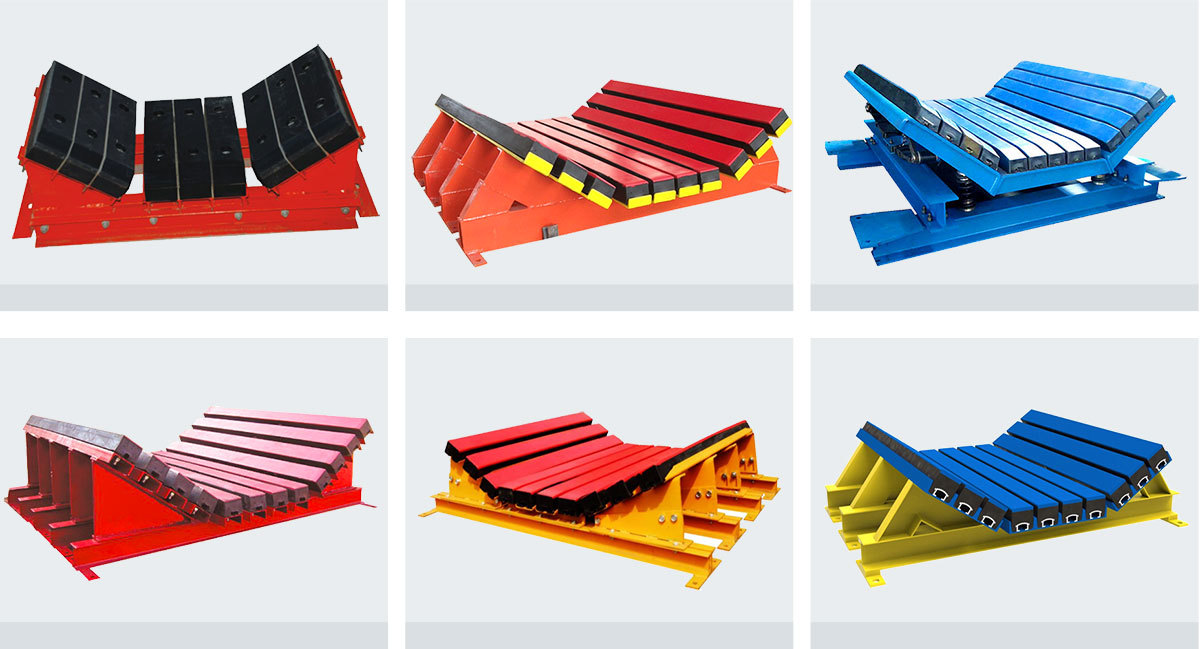

⑦ We can provide various impact beds according to your requirements.

Impact Bars&Bed is used for vibration damping protection of conveyor belt at material loading blanking point. The impact bed is mainly designed to instead of impact idler, impact bed consists of impact bar, the impact bar is made of high elasticity special rubber,which can absorb the impact force effectively when the material dropping, greatly reduce the impact to the conveyor belt and improved the stress state of the loading point. Special UHMW used in the impact bar surface, which greatly reduce the coefficient of friction between belt and impact bar and has good features of wear resistant. To the conveyor belt, the application of the impact bed ensures stress uniform, effectively prevent belt longitudinal tear due to the idler roller fracture or fall off to extend its life.

ADVANCEMENTS

① Low friction coefficient UHMWPE engineered plastic impact block;

② Avoid belt damage by supporting it effectively;

③ Avoid splash back of the material;

④ Only need to change the impact block reducing maintenance costs;

⑤ Designed as a whole mould which is more convenient to assemble and maintain;

⑥ Easy to transform and make a better work efficiency;

⑦ We can provide various impact beds according to your requirements.

Previous:

Next:

Key words:

Message

Related products