Products

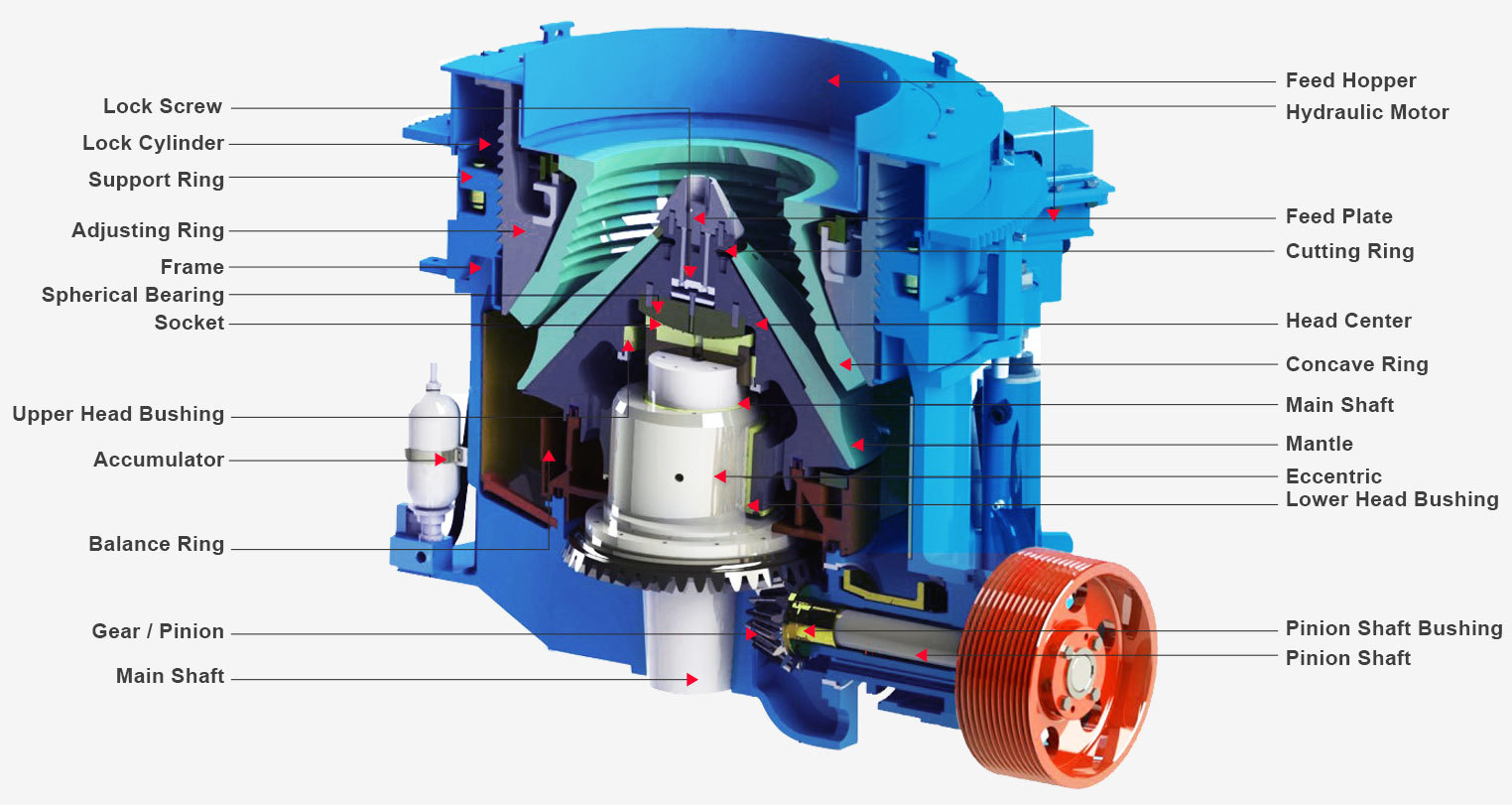

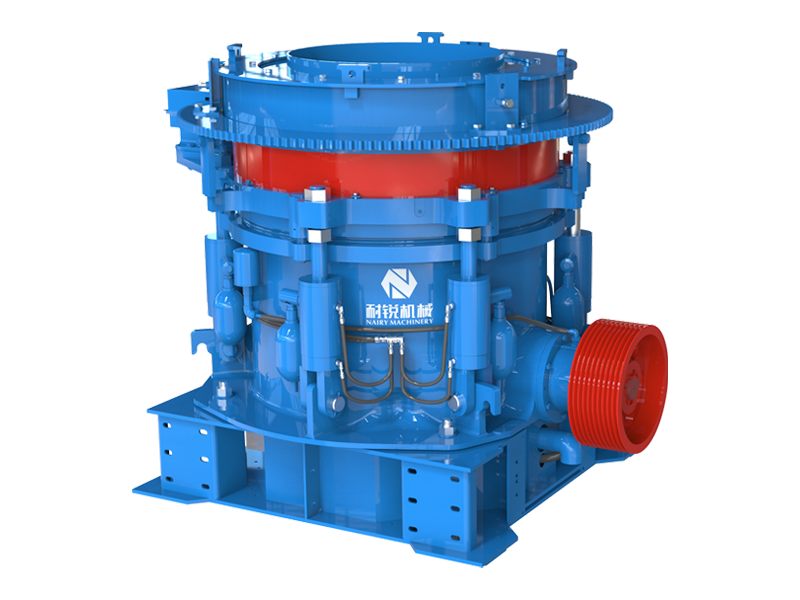

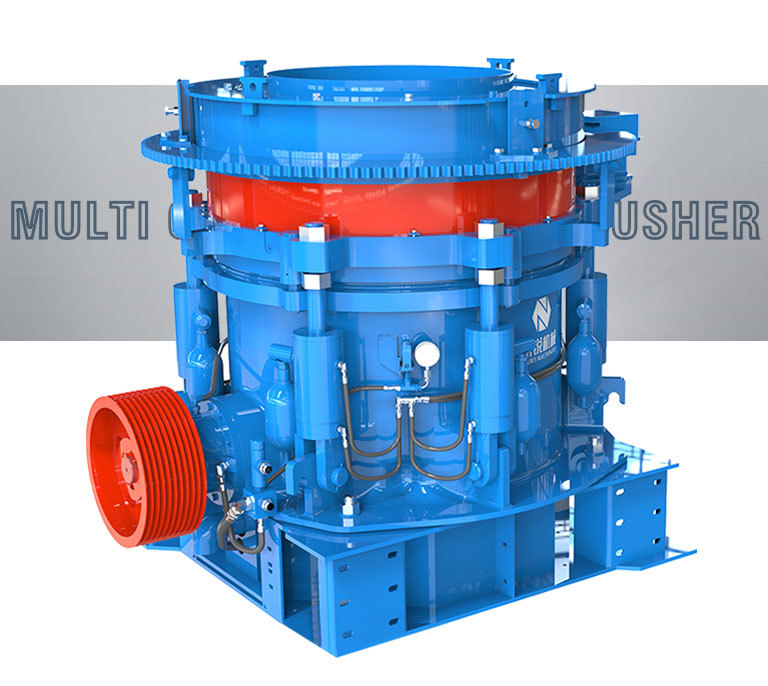

Multi cylinder cone crusher

Category:

Product Description

NHP series multi-cylinder cone crusher is the perfect combination of crushing speed, stroke, and crushing chamber design. This combination is proved to be revolutionary.It not only improves the production capacity and product quality but also expands the application range.NHP multi-cylinder cone crusher offers unmatched crushing performance in medium, fine and ultra-fine crushing operations.

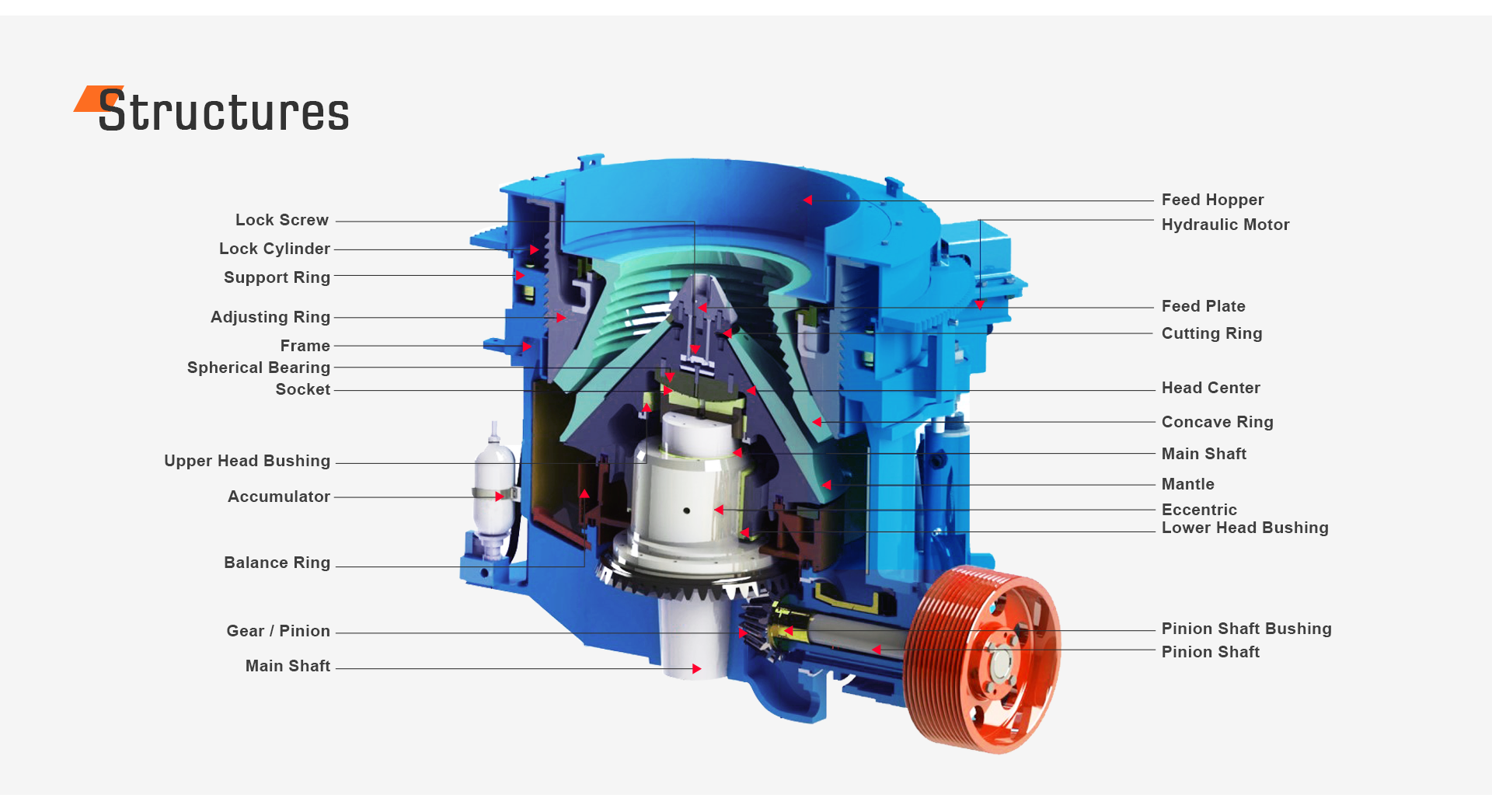

01.Feed opening size enlarged and eccentric distance,realized laminating crushing, making higher production and better particle shape.

01.Feed opening size enlarged and eccentric distance,realized laminating crushing, making higher production and better particle shape.

02.The main shaft and drive shaft adopt high strength alloy material and advanced heat treatment process to ensure the long-term stable operation of the equipment.

03.The liner plate adopts advanced adjustment mode, making stable feeding and high-usage of liner plate.

04.Advanced hydraulic protection device provides efficient protection to equipment.

05.High automation, simple operation make high working efficiency.

06.Advanced sealing method ensures the lubrication system cleanness.

07.Simple equipment maintenance. Easy replacement of the parts.

|

Model |

Power(kw) |

Capacity under CSS(t/h) |

|||||||||

|

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

||

|

NHP200 |

160 |

90-120 |

120-150 |

140-180 |

150-190 |

160-200 |

170-220 |

190-235 |

210-250 |

||

|

NHP300 |

220 |

115-140 |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

|

|

NHP400 |

315 |

140-175 |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

325-430 |

360-490 |

410-560 |

465-630 |

|

NHP500 |

400 |

175-220 |

230-290 |

280-350 |

320-400 |

345-430 |

365-455 |

405-535 |

445-605 |

510-700 |

580-790 |

|

NHP800 |

630 |

260-335 |

325-425 |

385-500 |

435-545 |

470-600 |

495-730 |

545-800 |

600-950 |

690-1050 |

785-1200 |

Remarks: The above data is for reference only, as the production capacity of the crusher is affected by the crushing ratio of the selected equipment, material hardness, feeding particle size composition, cycle load, water content in the feed, mud content, etc. For details, please consult our engineers .

NHP series multi-cylinder cone crusher is the perfect combination of crushing speed, stroke, and crushing chamber design. This combination is proved to be revolutionary.It not only improves the production capacity and product quality but also expands the application range.NHP multi-cylinder cone crusher offers unmatched crushing performance in medium, fine and ultra-fine crushing operations.

01.Feed opening size enlarged and eccentric distance,realized laminating crushing, making higher production and better particle shape.

02.The main shaft and drive shaft adopt high strength alloy material and advanced heat treatment process to ensure the long-term stable operation of the equipment.

03.The liner plate adopts advanced adjustment mode, making stable feeding and high-usage of liner plate.

04.Advanced hydraulic protection device provides efficient protection to equipment.

05.High automation, simple operation make high working efficiency.

06.Advanced sealing method ensures the lubrication system cleanness.

07.Simple equipment maintenance. Easy replacement of the parts.

|

Model |

Power(kw) |

Capacity under CSS(t/h) |

|||||||||

|

10mm |

13mm |

16mm |

19mm |

22mm |

25mm |

32mm |

38mm |

45mm |

51mm |

||

|

NHP200 |

160 |

90-120 |

120-150 |

140-180 |

150-190 |

160-200 |

170-220 |

190-235 |

210-250 |

||

|

NHP300 |

220 |

115-140 |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

|

|

NHP400 |

315 |

140-175 |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

325-430 |

360-490 |

410-560 |

465-630 |

|

NHP500 |

400 |

175-220 |

230-290 |

280-350 |

320-400 |

345-430 |

365-455 |

405-535 |

445-605 |

510-700 |

580-790 |

|

NHP800 |

630 |

260-335 |

325-425 |

385-500 |

435-545 |

470-600 |

495-730 |

545-800 |

600-950 |

690-1050 |

785-1200 |

Remarks: The above data is for reference only, as the production capacity of the crusher is affected by the crushing ratio of the selected equipment, material hardness, feeding particle size composition, cycle load, water content in the feed, mud content, etc. For details, please consult our engineers .

Previous:

Key words:

Message

Related products