Products

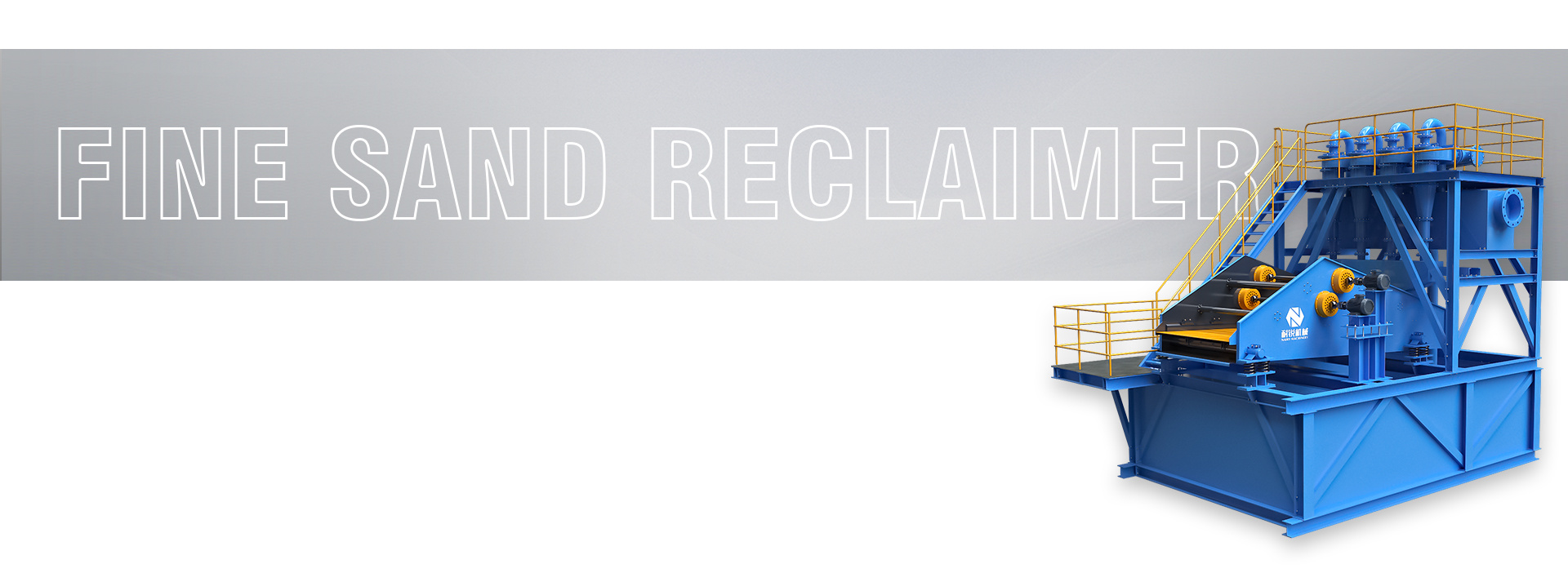

Fine sand reclaimer

Category:

Product Description

FSPD series fine sand reclaimer is mainly used for fine sand recycling in aggregate wet production fine sand recovery, mine tailings treatment etc, can recycle fine and above 325 mesh in incoming materials, the comprehensive recovery rate can reach more than 90%, single set of equipment processing capacity varies from 50m³/h to 500m³/h,according to different size.

FSPD series fine sand reclaimer is mainly composed of hydrocyclone, dewatering screen, upper tank, lower tank, slurry pump and related pipe fittings. The cyclone feeder shares a water tank with the material under the dewatering screen, and the material under the sieve forms a self-closed cycle, which not only saves the land occupation and construction of the cyclone feeding pump pool, but also improves the recovery rate of fine sand.

Sand washing wastewater enters the tank under the fine sand reclaimer through the pipeline or sink, and is transported to the hydrocyclone at high speed under the action of the slurry pump, and the fine sand of 0-0.16mm is centrifuged, classified and concentrated in the cyclone, and finally discharged from the grit nozzle into the dewatering screen, and after dewatering by the dewatering screen, one part enters the finished sand yard to adjust the fineness modulus of the sand, and the rest is sent to the stockpile for storage. After separation, the wastewater and a small amount of fine sand enter the upper tank from the overflow port of the cyclone, and part of it returns to the lower tank through the upper tank, and the flow rate is adjusted through the pipeline and valve, which realizes the recycling of fine sand and achieves the effect of high efficiency and energy saving; The other part is discharged from the upper tank into the drainage ditch and enters the subsequent wastewater treatment system.

|

Model |

Screen hole size (mm) |

Sieve surface inclination |

Treated water volume (m³/h) |

Power (kw) |

|

FSPD-50 |

0.25-0.5 |

-5° |

20-50 |

21 |

|

FSPD-100 |

0.25-0.5 |

-5° |

50-100 |

28 |

|

FSPD-200 |

0.25-0.5 |

-5° |

100-200 |

44 |

|

FSPD-300 |

0.25-0.5 |

-5° |

200-300 |

56 |

|

FSPD-400 |

0.25-0.5 |

-5° |

300-400 |

70 |

|

FSPD-500 |

0.25-0.5 |

-5° |

400-500 |

97 |

FSPD series fine sand reclaimer is mainly used for fine sand recycling in aggregate wet production fine sand recovery, mine tailings treatment etc, can recycle fine and above 325 mesh in incoming materials, the comprehensive recovery rate can reach more than 90%, single set of equipment processing capacity varies from 50m³/h to 500m³/h,according to different size.

FSPD series fine sand reclaimer is mainly composed of hydrocyclone, dewatering screen, upper tank, lower tank, slurry pump and related pipe fittings. The cyclone feeder shares a water tank with the material under the dewatering screen, and the material under the sieve forms a self-closed cycle, which not only saves the land occupation and construction of the cyclone feeding pump pool, but also improves the recovery rate of fine sand.

Sand washing wastewater enters the tank under the fine sand reclaimer through the pipeline or sink, and is transported to the hydrocyclone at high speed under the action of the slurry pump, and the fine sand of 0-0.16mm is centrifuged, classified and concentrated in the cyclone, and finally discharged from the grit nozzle into the dewatering screen, and after dewatering by the dewatering screen, one part enters the finished sand yard to adjust the fineness modulus of the sand, and the rest is sent to the stockpile for storage. After separation, the wastewater and a small amount of fine sand enter the upper tank from the overflow port of the cyclone, and part of it returns to the lower tank through the upper tank, and the flow rate is adjusted through the pipeline and valve, which realizes the recycling of fine sand and achieves the effect of high efficiency and energy saving; The other part is discharged from the upper tank into the drainage ditch and enters the subsequent wastewater treatment system.

|

Model |

Screen hole size (mm) |

Sieve surface inclination |

Treated water volume (m³/h) |

Power (kw) |

|

FSPD-50 |

0.25-0.5 |

-5° |

20-50 |

21 |

|

FSPD-100 |

0.25-0.5 |

-5° |

50-100 |

28 |

|

FSPD-200 |

0.25-0.5 |

-5° |

100-200 |

44 |

|

FSPD-300 |

0.25-0.5 |

-5° |

200-300 |

56 |

|

FSPD-400 |

0.25-0.5 |

-5° |

300-400 |

70 |

|

FSPD-500 |

0.25-0.5 |

-5° |

400-500 |

97 |

Previous:

Key words:

Product Brief

Product Features

Message

Related products