News

Gravel Washing Process

Release time:

Nov 24,2023

Common Process Of Gravel Washing

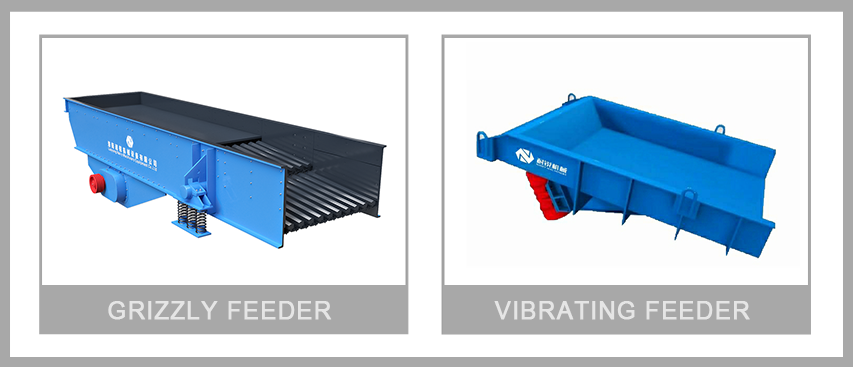

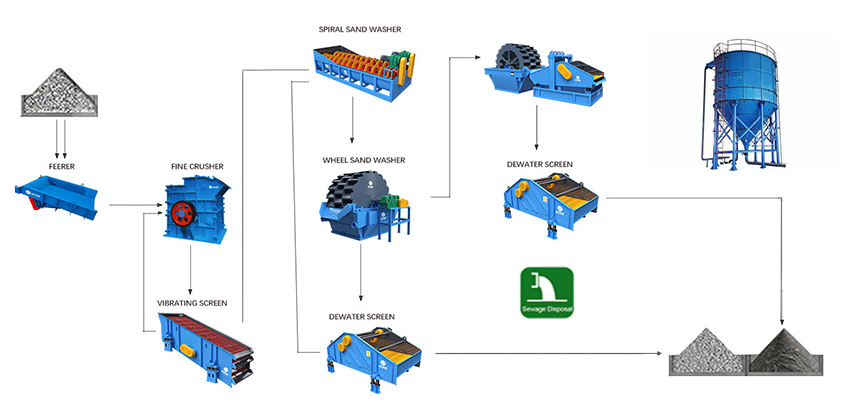

》 》Feeding

Feeding is the beginning of a gravel washing plant, which is usually completed by vibrating feeder, to conveying and supplying raw materials to the following equipment.

》 》Screening and conveying

Screening is a grading process that classify raw materials through vibratingscreen. In the sand and gravel washing line, different particle size sand and gravel need to be separated, and the graded products need to be transported to their respective fields.The equipment used in this process is usually linear vibrating screen and conveyor belt.

》 》Washing and dewatering

Washing is refer to a cleaning process finished by sand washing machine, which mainly wash out the impurities mixed in sand to get the purpose of clean sand. Dewatering screen is adopted for dewatering system, which realize the dewatering purpose through the vibration of screen, the water content of finished proucts down to 12%-15%.

》 》Fines recycling

The fines recycling is usually processed by desander cyclone, which can recover 0.074-3mm fine sand by the centrifugal force.

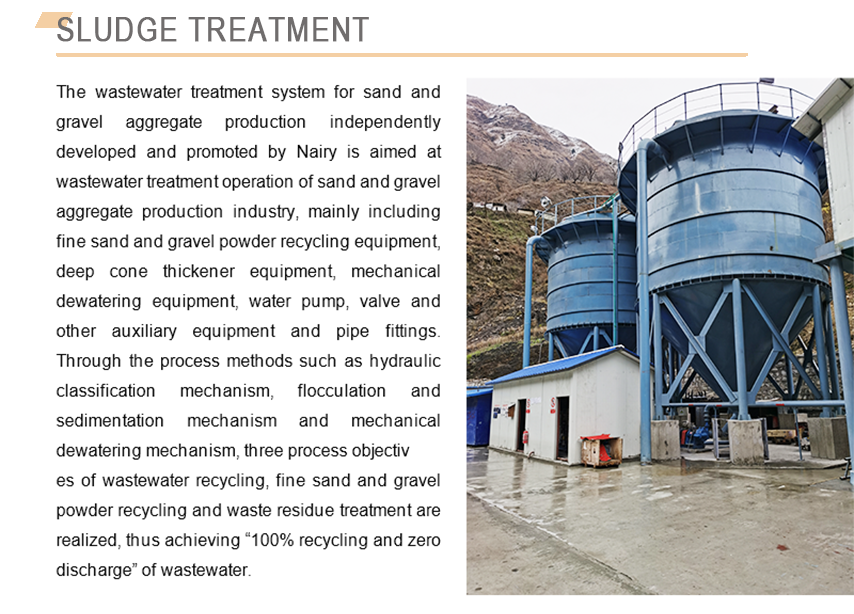

》 》Muddy water purification

Muddy water purification is composed of deep cone thickener and belt press. The water can be reused and mud realize dry discharge through this step.

Contact us to customize your own sand and stone cleaning solution.

Inquire now!

Compare Spiral Sand Washer And Wheel Sand Washer

》Spiral Stone Washer Machine

Spiral sand washer is a commonly used sand washing equipment. The structure of the spiral sand washing machine determines its purpose and method of use. It uses the buoyancy of water to separate dust and impurities from the stone material, and uses spiral blades for stirring to achieve the purpose of filtering water and removing impurities. It uses a central structure rotor and spiral blades installed on the central shaft and connected to a reducer for operation, mainly based on the principle that solid particles have different specific gravity and sedimentation rates in liquid, and then carries out classification treatment.When washing sand, when the spiral sand washer is running, one side of the spiral blade is to inject water resources, and the other side is to discharge rocks, mud, sand, and other wastes, and then deposit on the bottom of the spiral sand washer.

》Wheel Stone Washer Machine

Wheel type sand washing machine, also known as bucket type sand washing machine. It is driven by an electric motor and a reducer, which drives the impeller in the water tank to rotate continuously in a circular motion in the water tank.The gravel enters through the feed chute, rolls under the impeller, and then grinds each other to remove impurities covering the gravel surface and destroy the covering layer on the gravel surface. The water vapor layer promotes dehydration, and the impact force formed by the water flow will discharge impurities and foreign matter with a small specific gravity from the overflow tank, and then use the rotating blade to take away the clean sand and gravel, and finally discharge the sand and gravel directly and introduce it The discharge trough completes the sand and gravel cleaning process of the wheel sand washer.

Previous

Previous