News

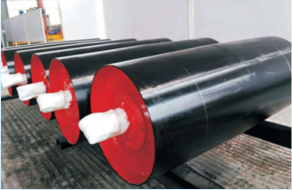

Main Component of Belt Conveyor - Pulley

Release time:

Nov 12,2024

The pulley is a critical component of a mining belt conveyor, typically including types such as drive pulleys, redirect pulleys, and tensioning pulleys. Below is a detailed description of each of their functions:

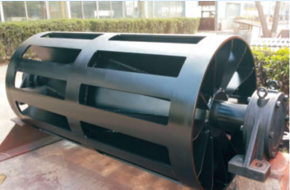

Drive Function (Drive Pulley):

The drive pulley is the core power component of the belt conveyor, connecting to a motor to generate torque that drives the conveyor belt, enabling continuous material transportation.

Drive pulleys typically have a high friction coefficient to ensure the belt does not slip, providing stable power output.

Support Function (Carrier Pulley):

Carrier pulleys are arranged under the conveyor belt to provide support, keeping the belt running smoothly and preventing sagging or misalignment.

The carrier pulleys are evenly distributed, helping to reduce bending and friction on the belt, thus extending the belt's lifespan.

Redirect Function (Redirect Pulley):

The redirect pulley changes the movement direction of the conveyor belt, commonly used for complex routes or multi-section conveying scenarios.

It allows the belt to turn flexibly at various points, adapting to the varied terrain demands in mining operations.

Tensioning Function (Tensioning Pulley):

The tensioning pulley adjusts its position to control the tension of the conveyor belt, ensuring the belt has the proper tightness to prevent slipping or loosening.

Adjusting the tensioning pulley also ensures the belt maintains even tension throughout operation, helping to prevent belt misalignment.

These different pulleys work together to ensure that the mining belt conveyor operates smoothly, efficiently, and reliably during material transportation, adapting to various terrains and operational conditions.

The pulley is one of the core components of a belt conveyor, directly affecting equipment efficiency and durability. Our company's pulleys have the following outstanding features:

Integral Casting of End Discs: Using lost foam casting technology, our pulleys are molded as a single piece, creating a uniform structure with balanced stress distribution. This results in high-strength pulleys that are well-suited to heavy-duty applications.

Keyless Connection Structure: The drive pulley utilizes a bushing connection, while the redirect pulley uses an interference fit, eliminating stress concentration issues that traditional keyways cause on shafts. This greatly reduces shaft failure rates, enhancing both durability and safety.

High-Quality Shell Material: The pulley shell is made from premium steel plates that are precision-rolled, ensuring uniform material properties that meet high-strength requirements. This controls radial runout within strict limits, effectively reducing vibration during operation.

Rigorous Balance Testing: Each pulley undergoes individual balance testing before leaving the factory, ensuring stability during high-speed operation and preventing vibration and wear due to imbalance.

Special Vulcanized Rubber Layer: The pulley surface is covered with a proprietary vulcanized rubber layer to enhance friction and significantly improve wear resistance. This not only prevents slippage but also extends the pulley’s lifespan.

Optimized Design: Utilizing advanced finite element analysis for precise design and optimization, our high-strength pulleys offer reliable mechanical performance and structural quality, meeting the demands of complex working conditions.

These features make our pulleys highly durable, stable, and adaptable, making them ideal components for belt conveyors in heavy-duty mining, metallurgy, and similar applications.

Previous

Next

Previous

Next

Nov 12,2024

Nov 05,2024

Oct 29,2024

Oct 23,2024